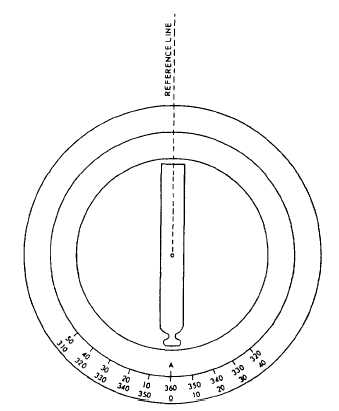

Figure 13-10.-Setting the vernier at zero-zero.

The horizontal limb is paired with another

circle (the vernier plate), which is partially

graduated on either side of zero graduations

located 180° apart on the plate. When the

telescope is in the normal (upright) position, the

A vernier is located vertically below the eyepiece,

and the B vernier, below the objective end of the

telescope. The zero on each vernier is the indicator

for reading the sizes of horizontal angles turned

on the horizontal limb.

Figures 13-10 and 13-11 illustrate the method

of turning an angle of 30° from a reference line

with a transit.

1. With the transit properly set over the point

or station, bring one of the horizontal verniers

near zero by hand; clamp the upper motion; and,

by turning the upper tangent screw, set one

vernier at 0°, usually starting with the A vernier

(fig. 13-10). Train the telescope to sight the marker

(range pole, chaining pin, or the like) held on the

reference line; clamp the lower motion; and, by

using the lower tangent screw, set the line of sight

on the marker.

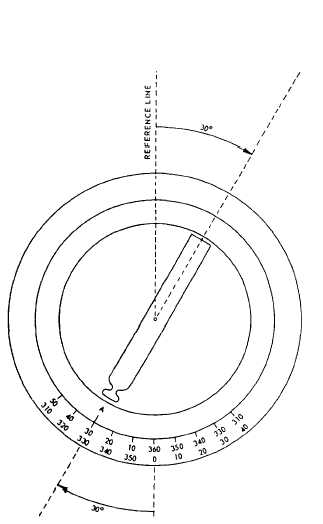

Figure 13-11.-Setting an angle exactly on the vernier zero.

2. Release the upper motion and rotate the

telescope to bring the zero on the A vernier in line

with th3 30° graduation on the horizontal limb,

as shown in figure 13-11. To set the vernier

exactly at 30°, use the upper tangent screw. You

may use a magnifying glass to set the vernier easily

and accurately.

3. Mark the next point with a marker, and

follow the procedures for establishing a point or

station.

Similarly, you may use the procedures above

to measure a horizontal angle by sighting on two

existing points and reading their interior angle.

In addition, the following hints may help you

when you are taking horizontal measurements:

1. Make the centering of the line of sight as

close as possible by hand so that you will not turn

the tangent screw more than one or two turns.

Make the last turn of the tangent screw clockwise

to compress the opposing springs.

13-10