The total weight of fractions plus the weight

of the material that reached the pan comes to

359.0 g. The weight of the sample originally was

359.1 g; there is an error here of 0.1 g. At the

lower right, you can see how the percentage of

error is computed. The maximum permissible

percentage of error is normally (±) 1 percent. If

the percentage exceeds the maximum, the test

must be rerun. For an error smaller than the max-

imum permissible, correction is made by adding

the value of the error to the largest amount listed

as retained. The value of the error in this case is

0.1 g. The largest amount retained is 83.3 g for

the No. 20 sieve. This amount would be changed

to 83.4 g.

SIEVE ANALYSIS WITH PREWASH-

ING.— When inspection indicates that a sample

contains an excessively high portion of superfine

material (material that passes the No. 200 sieve),

analysis with prewashing is done as follows:

1. Oven-dry the sample.

2. Weigh and record the total weight after

cooling.

3. Place the sample in a clean pan and add

clean water until it is completely covered. Allow

it to soak until it is completely disintegrated—

from 2 to 12 hr. Stir to break up lumps and hasten

the action.

4. Wash the material thoroughly on a No. 200

sieve under running water and discard the material

that passes.

5. Oven-dry and reweigh. Record the dif-

ference between this weight and the original

weight as washing loss.

6. Continue as for sieve analysis, dry.

Figure 15-32 shows a data sheet for sieve

analysis with prewashing. The ovendry weight of

the original sample was 75.0 g; the ovendry weight

after prewashing was 55.0 g; therefore, the

washing loss was 75.0 -55.0 or 20.0 g. The sum

of the weights retained (53.0 g, the total of col-

umn b) plus the 2.0 g that, in spite of prewashing,

was still left in the sample to pass the No. 200

sieve, equals 55.0 g. This was the original weight

after prewashing. Therefore, no error was made.

Hydrometer Analysis

As you learned in the preceding discussion, the

determination of grain size distribution by sieve

analysis is limited to those materials larger than

the No. 200 (0.074-mm) sieve. For uses such as soil

classification, this is sufficient since grain size

distribution is not used to classify fine-grained

soils. For determination of frost susceptibility,

however, the distribution of particles smaller than

the No. 200 sieve is necessary. A soil is considered

frost susceptible if it contains 3 percent or more

by weight of particles smaller than 0.020 mm in

diameter. Frost susceptibility should always be

considered in areas subject to substantially

freezing temperatures, since repeated freezing,

and subsequent thawing, of water in the soil can

seriously affect the ability of the soil to support

a structure. Hydrometer analysis is the test used

to determine the grain size distribution of the soils

passing the No. 200 sieve.

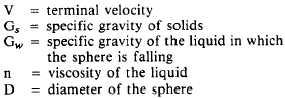

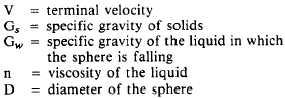

Hydrometer analysis is based on Stokes’ law,

which relates the terminal velocity of a free-falling

sphere in a liquid to its diameter. The relation is

expressed by the following equation.

Where:

It is assumed that Stokes’ law can be applied

to a mass of dispersed soil particles of various

shapes and sizes. Larger particles settle more

rapidly than the smaller ones. The hydrometer

analysis is an application of Stokes’ law that per-

mits the calculation of the grain size distribution

in silts and clays, where the soil particles are given

the sizes of equivalent spherical particles.

The density of a soil-water suspension depends

upon the concentration and specific gravity of the

soil particles. If the suspension is allowed to stand,

the particles will gradually settle out of the suspen-

sion, and the density will be decreased. The

hydrometer is the instrument used to measure the

density of the suspension at a known depth below

the surface. The density measurement, together

with knowledge of specific gravity of the soil

particles, determines the percentage of dispersed

soil particles in suspension at the time and depth

of measurement. Stokes’ law is used to calculate

the maximum equivalent particle diameter for the

material in suspension at this depth and for the

elapsed time of settlement. A series of density

measurements at known depth of suspension and

at known times of settlement gives the percentages

of particles finer than the diameters given by

Stokes’ law. Thus the series of readings will reflect

the amount of different sizes of particles in the

fine-grained soils. The particle diameter (D) is

15-24