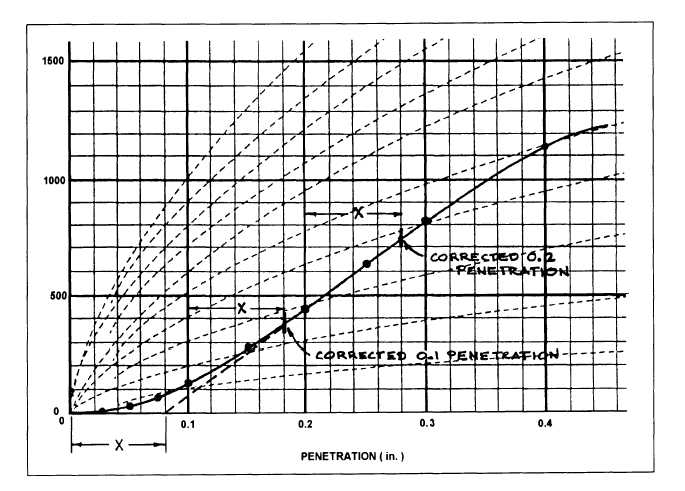

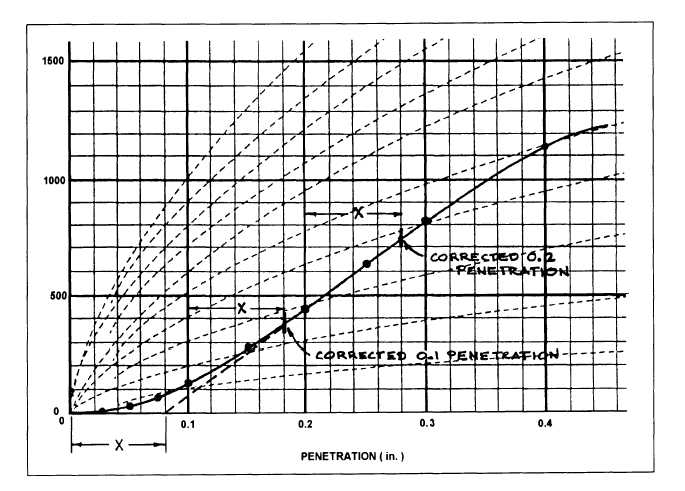

Figure 13-12.—Adjusting the zero point of the curve.

indicates that the proving-ring dial used for this test

necessary to obtain the true or corrected load. In this

contained a previously determined index error of 0.003

inch. An error of this kind develops as a result of

repeated compressions of the proving ring during

testing.

The figures under total load are the results obtained

by multiplying the corrected dial reading by the

proving-ring constant. Each unit load was obtained by

dividing the total load by 3.

Figure 13-11B is the reverse side of the CBR test

data sheet. This side of the data sheet is used to plot the

unit loads against the penetration depths to determine if

a correction to the unit load is necessary.

In figure 13-11B you see the curve for sample

SF-PI-4 that we have been discussing. The convex shape

of this curve indicates that no corrections were

necessary. Sometimes, however, surface irregularities in

the soil sample or disturbances during the test will result

in curves having an initially concave shape, such as

shown in figure 13-11B for samples SF-PI-5 and

SF-PI-6. This shape indicates that a correction is

case, you must first adjust the zero point of the curve.

Figure 13-12 illustrates the procedure you should use to

adjust the zero point. First, draw a line that is tangent to

the steepest portion of the concave curve and extend the

tangent to the zero base line. The point of intersection

of the tangent and the base line is the new

zero-penetration point. The distance of the new zero

point from the original zero point (distance X) is the

distance that the 0.1 and 0.2 points are moved to the right

to establish the corrected unit load.

Finally, let’s look again at figure 13-11A and discuss

how the CBR values are determined. To compute the

CBR values, you divide the unit load (or corrected unit

load) at 0.1 and 0.2 inch by the standard unit loads of

1,000 and 1,500 psi, respectively. Each result is then

multiplied by 100 to obtain the CBR in percent. The

CBR is usually selected at 0.1 inch; however, when the

CBR at 0.2 inch is greater, you should first rerun the test

and then if the check tests give similar results at 0.2-inch

penetration, the CBR at 0.2 inch should be used.

13-15