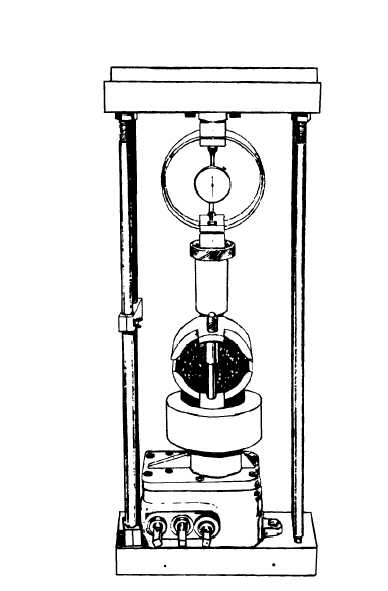

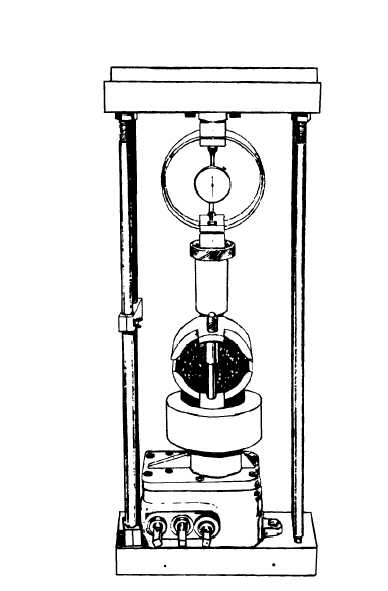

Figure 13-37.-Marshall stability testing head mounted in CBR

jack.

however, we’ll briefly discuss the method here. The

apparatus used for testing stability and flow of the

specimen is shown in figure 13-37. This figure shows a

Marshall stability testing head containing the specimen,

mounted on the plunger of a bearing-ratio jack. This test

head consists of upper and lower breaking heads. A

5,000-pound proving ring with a dial is installed in the

jack.The test for stability is made by applying pressure

gradually, about 2 inches per minute, and reading the

maximum pressure the specimen sustains before failing.

The test for flow is carried out simultaneously by

holding a flow meter over the testing head guide rod

(vertical rod shown running through the testing heads)

and reading the meter at the instant the specimen fails

under pressure. This reading indicates the flow value of

the specimen in inches to the nearest 0.01 inch.

HAZARDOUS-MATERIAL

PRECAUTIONS

Although the Navy has exacting definitions for the

terms hazardous material, hazardous chemical, and

hazardous substance, let’s, for simplicity of discussion,

lump them all together and simply say that these

materials, because of their quantities, concentration, or

hazardous properties, pose a substantial hazard to

human safety and health or to the environment. The risks

associated with these materials include flammability,

toxicity, corrosivity, and reactivity. From your study of

this chapter and the EA3 TRAMAN, you should be able

to see readily how many of the materials you test, or use

for testing, in the laboratory fall within the above

definition. Heated asphalt can cause severe burns if

allowed to come into contact with the skin, and asphalt

cutbacks are highly flammable with low flash points.

Some of the chemicals that you will use in materials

testing are highly toxic and corrosive. Others react with

water, forming explosive gases; however, not all of the

hazardous materials that an EA uses are confined to the

laboratory. For example, the ammonia used with

reproduction equipment gives off highly toxic fumes.

For these and other reasons, all such materials must be

handled, used, stored, and disposed of properly and with

caution. As a crew leader, you must recognize the threat

that hazardous materials pose to all personnel present

on the jobsite and take action to prevent mishaps.

Material Safety Data Sheets (MSDS) must be

received and maintained for all hazardous materials in

your work space. The MSDS identifies any hazards

associated with exposure to a specific material. It

identifies personal protective equipment and other

safety precautions required as well as first aid or medical

treatment required for exposure. By federal law, a crew

leader is required to inform his or her crew members of

the risks and all safety precautions associated with any

hazardous material present on the jobsite. A good time

for you to do this is during your daily standup safety

lectures.

A safe practice concerning hazardous materials is to

not draw more material than will be used in 1 day.

Storing hazardous materials in the workspace or on the

jobsite requires the use of approved storage containers.

Some of these materials require separate storage; for

example, flammable materials and corrosive materials

cannot be stored together. When in doubt about storage

requirements, consult with your supervisor or the safety

officer.

Excess hazardous materials or hazardous waste

products must be disposed of through an authorized

13-50