Oven-dry and weigh the material retained. Then you can

calculate the percentage of clay lumps and friable

particles using the following equation:

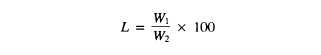

Where:

P = percent of clay lumps and friable

particles

w1 = original weight of test sample

W2 = weight of retained sample after wet

sieving and drying

Test for Undesirable Lightweight Material.—

Soft, laminated pieces of aggregate, such as chert or

shale, are harmful to concrete. Coal and lignite, also, are

harmful and are distinguished from the lightweight

materials by the brownish black or black color of the

particles. Visual examination of the coarse aggregate

will often show these minerals. The amount of these

minerals in an aggregate can be determined by

submersing the aggregate in a liquid with a specific

gravity that will allow the shale or other light particles

to float and heavier particles to sink.

For specific testing procedures, you should refer to

ASTM C 123 or to NAVFAC MO-330. Briefly, you

perform the test by first sieving the dried sample over a

No. 50 sieve for fine aggregate and a No. 4 sieve for

coarse aggregate. Weigh the sample and then place it

into a heavy liquid, such as zinc chloride (specific

gravity of 1.95 at 78°F). Agitate the mixture to allow the

lightweight particles to rise to the surface and skim them

off. When repeated agitation causes no further particles

to rise, you wash the sample in alcohol and then dry and

weigh it. The percentage of undesirable, lightweight

particles can then be calculated using the following

formula:

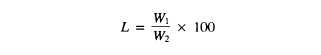

Where:

L = percentage of lightweight material

W1 = dry weight of lightweight material

W2 =

dry weight of initial sample retained

on No. 50 sieve for fine aggregate or

No. 4 sieve for coarse aggregate

Color Test for Organic Matter.— Any sand that

gives a color darker than the standard of this test

probably contains an excess of organic matter that will

reduce the strength of the concrete in which the sand is

used. If you determine that organic matter is present, it

is possible that it can be removed by washing; if not,

better sand should be obtained. If neither of these things

can be done, it will be necessary to use a lower

water-cement ratio and control the concrete production

carefully to obtain the desired strength.

For the color test, you will need the items illustrated

in figure 13-17. To perform the test, you add the sample

being tested to a solution of sodium hydroxide and

water. After allowing the sample to stand for 24 hours,

you then compare the color of the liquid above the

sample to a standard color solution consisting of tannic

acid, alcohol, and sodium hydroxide. If the liquid above

the sample is darker in color than the standard solution,

the sand may contain organic impurities. NAVFAC

MO-330 provides full details for preparing the solutions

and performing the test.

As an alternative, the color of the liquid above the

sample can be compared with the colors given in the

ASTM standard color plate. Then decide whether the

sand contains an excessive amount of organic matter.

SPECIFIC GRAVITY, ABSORPTION, AND

SURFACE MOISTURE.— These tests must be

performed on the aggregate before the necessary

calculations can be made to design a concrete mixture.

For aggregates used in portland cement concrete,

measurements are made to determine the bulk specific

gravity of the aggregates in a saturated, surface-dry

(SSD) condition. Specific gravity is thus based on

determining the total volume occupied by the aggregate

particles, including the permeable pore space.

Absorption and surface moisture determinations are

necessary to calculate the amount of mixing water used

in a concrete mixture. Absorption, determined as a

percentage, represents the moisture content of the

aggregate when the aggregate is in a SSD condition.

Surface moisture is the water that is present in both fine

and coarse aggregate, exceeding that which corresponds

to a SSD condition.

Concrete-mixture design is discussed at the EA1

level in Part 2 of this TRAMAN.

Specific Gravity and Absorption, Coarse

Aggregate (ASTM C 127).— The summarized steps in

determining the bulk specific gravity of SSD coarse

13-24