the bulkheads, you must tighten the packing before

designated for air testing are provided with fittings for

attaching the air test set. In the case of tanks, you may

conducting the air test to maintain the air pressure.

use sounding tubes or air escapes to connect the air test

M a ke s u r e t h a t t h e c r ew i s awa r e o f t h e

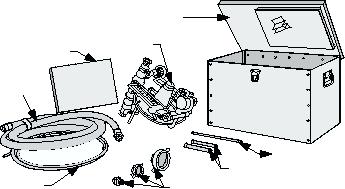

set. Figure 3-19 shows the air test set that is provided

compartment air test being conducted. Post signs at

for shipboard use. The manufacturer's technical

every possible access to the compartment(s) being

manual, provided with each set, gives detailed

tested. If an observer is stationed inside the

instructions for operating the air test set.

compartment during the compartment air test, each

access to the compartment must have someone posted

at the access closure. The guards are to prevent the

access closure from being opened until the excessive

pressure within the compartment is relieved. The air

STORAGE BOX

test pressure used in a compartment air test is relatively

low. However, a dangerous total force can be

AIR TEST SET

INSTRUCTION

MANUAL

d eve l o p e d o n q u i c k - a c t i n g d o o r s a n d h a t c h e s .

CHARGE LINE

Personnel should be instructed not to attempt to open

EXTENSION

HOSE

quick-acting doors or hatches when a compartment is

under air test. A person opening these doors or hatches

while the compartment is under pressure could likely

SENSING LINE PROBE

sustain severe injuries.

EXTENSION LEGS

SENSING LINE

EXTENSION

PIPE TO HOSE ADAPTERS

When conducting a compartment air test on a large

DCf0317

compartment, use as many personnel as required to

check for leaks. The personnel involved with the test

need to maintain communication with each other. The

X40J (salt and pepper or international orange) rig can

Figure 3-19. Air test set.

be used, allowing you to have an isolated circuit

without interruptions. When you are conducting a

The information contained in the ship's schedule

compartment air test, any loss of pressure in excess of

of watertight integrity tests and inspections must be

the allowable drop listed in the schedule over the

strictly adhered to when conducting compartment air

specified period of time indicates deterioration of the

tests. The air test pressure listed in the schedule must

watertight integrity of the compartment. If corrective

NEVER be exceeded. You can seriously damage the

measures are beyond the capacity of ship's force, the

structures and boundaries of the compartment being

compartment must be listed as UNSATISFACTORY.

tested if the recommended pressure is exceeded.

You must then request that repairs be completed during

the next availability.

Before starting an air test, you need to conduct a

visual inspection of the compartment and repair all the

While the compartment is under test, leaks will be

leaks that you find. Notify the engineer officer, the

disclosed by hissing or whistling noises as the air

DCA, and the OOD of your intent to conduct a

escapes. All leaks should be located, marked, and

compartment air test and which compartments will be

listed for corrective action. You should repair all leaks

involved. Also, have an Electrician's Mate (EM) assist

that were found and then test the compartment again. If

in de-energizing the electrical push-button alarms and

the allowable pressure drop is again exceeded on this

remote-controlled valves for sprinkling, flooding, or

test, apply a soap solution to the boundaries of the

counterflooding systems if any are installed in the

compartment and to all joints, fittings, and closures.

compartment to be tested. These devices have

When the air pressure is applied, bubbles will be

diaphragm covers and would be activated when the air

formed by escaping air, thus indicating the location of

test pressure is admitted to the compartment unless

the leaks.

they had been previously de-energized.

The observer inside the compartment will have a

All fittings that serve the compartment must be

lighted candle. As the observer goes over areas where

secured or blanked off before the air test is conducted.

leaks are suspected, the deflection of the flame will

If any rotating shafts or other moving parts penetrate

indicate the location of leaks.

3-23