Except as otherwise indicated, portable

Multiple-leg, wire-rope slings are shackled or

safety-hooked to lugs, rings, eyebolts, or lifting eyes.

ordnance-handling equipment used ashore must be

They are either an integral part of the load or are

tested annually at 40 percent of the design load of the

attached temporarily during handling.

equipment. This testing schedule must be followed for

all ordnance-lifting equipment, unless specifically

Before you use any ordnance-handling equipment,

exempted by higher authority.

you should verify that it has been tested and that the test

date is current. Inspect the equipment for evidence of

Equipment that has satisfactorily passed the

wear, such as frayed threads, broken stitches, cuts,

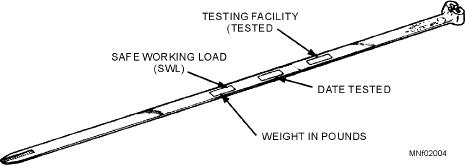

periodic load test requirements must have the name of

damaged cables, loose fasteners, missing safety

the testing facility, the date tested, and the safe working

keepers, bent hooks, and so forth. If any such damage is

load (SWL) stenciled in legible, contrasting colored

noted, remove the equipment from service.

paint on a conspicuous surface, or this information

may be stamped or etched on a tag that is securely

MK 95 MOD 0 TORPEDO SLING.--Although

its nomenclature indicates it is used with torpedoes,

attached to the equipment. See figure 2-4. New

this sling is also used with other cylindrically shaped

ordnance-handling equipment, received in original

weapons that are 21 inches in diameter and within its

packaging if an inspection shows that the equipment is

rated lifting capacity of 5,000 pounds. Fabricated of

free of defects, may have the test date changed to the

nylon webbing with a loop that is reinforced with a

current date without retest. A record of each periodic

leather pad at each end, the sling is used for loading the

test must be maintained by the facility performing the

Mk 67 mine aboard submarines. As shown in figure

periodic test.

2-5, the sling is wound twice around the mine with one

For further information regarding the testing of

loop inserted through the other to form a double-wrap

ordnance-handling equipment, refer to Periodic

choker hitch. The loops are reinforced with leather

Te s t i n g A r ra n ge m e n t s f o r O rd n a n c e H a n d l i n g

wear pads, and both sides of the body have nylon wear

Equipment, NAVSEA SG420-AP-MMA-010.

straps so that either side may bear directly against the

mine without chafing.

Lifting equipment, used for handling ammunition

and explosives, specifically mines, includes adapters,

MK 99 MOD 0 WEAPONS-HANDLING

booms, hoists, lifting attachments, and slings. The

SLING.--The Mk 99 Mod 0 weapons-handling sling

following subsections discuss various types of

is used at dockside and aboard ammunition ships for

handling equipment and their uses.

loading combatant ships with crated mines and

palletized unit loads of mines. This sling, as shown in

Slings

figure 2-6, consists of four swiveled safety hooks, each

attached to a flexible, galvanized 1/2-inch, wire-rope

In the assembly areas, slings are used mainly for

leg. The four legs are joined to a 5 1/2-inch lifting ring

crating, uncrating, and marrying various sections of

that is compatible with standard cargo lifting gear used

the mines. They are used for shipboard loading and

at dockside or aboard ammunition ships. Its rated

off-loading of mines at dockside and for transferring

lifting capacity is 6,000 pounds. The sling is used for

the mines between ships at sea. Slings can be classified

lifting one crated Mk 56 mine.

into the following two groups:

MK 101 MOD 0 MINE SLING.--Except for its

Nonmetallic nylon slings form a choker hitch

shorter length, the Mk 101 Mod 0 mine sling, as shown

around the body of the mine or the mine component.

in figure 2-7, is similar to the Mk 95 Mod 0 torpedo

Figure 2-4.--Weight test inspection tag.

2-15