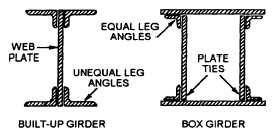

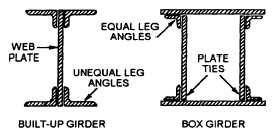

Figure 1-39.—Typical built-up girders.

which are, in turn, supported by columns. The horizontal

members or beams that connect the exterior columns are

called spandrel beams. If you add additional rows of

columns and beams, there is no limitation to the area of

floor and roof that can be supported using skeleton

construction. One limitation on using skeleton

construction, however, is the distance between columns.

Oftentimes, large structures, such as aircraft

hangars, may require greater distances between

supports than can be spanned by the standard structural

steel shapes. In this case, one of several methods of

long-span steel construction is used. One method uses

built-up girders to span the distances between supports.

Two types of built-up girders are shown in figure 1-39.

As seen in this figure, the built-up girder consists of steel

plates and shapes that are combined together to meet the

necessary strength. The individual parts of these girders

are connected by welding or riveting.

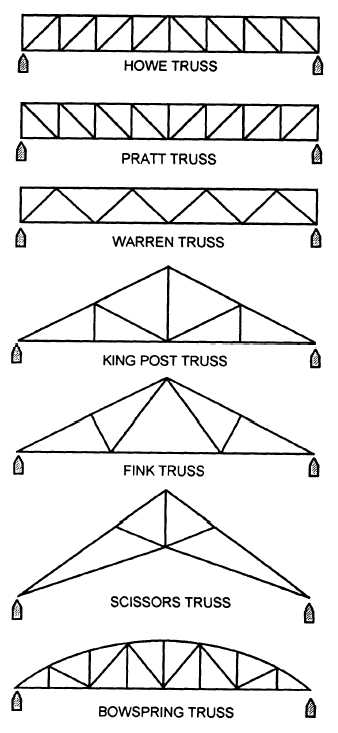

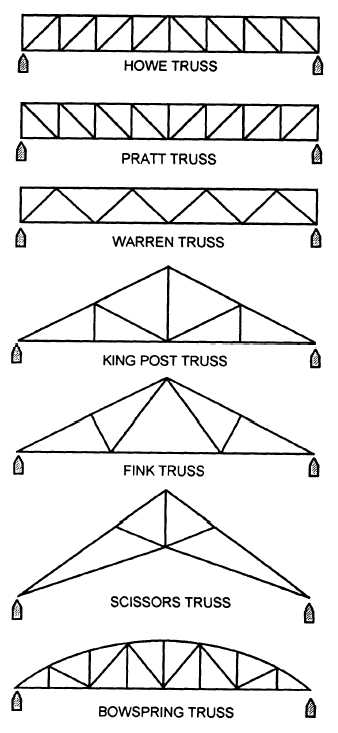

Another method, which is usually more

economical, is to use a truss to span large distances. As

you learned in the EA3 TRAMAN, a truss is a frame-

work of structural members consisting of a top chord,

bottom chord, and diagonal web members that are

usually placed in a triangular arrangement. (See figs.

1-40 and 1-41.) As shown in figure 1-40, trusses can be

fabricated to conform to the shape of nearly any roof

system.

A third long-span method, although not as versatile

as trusses, is the use of bar joists. Bar joists are much

lighter than trusses and are fabricated in several different

types. One type is shown in figure 1-42. Prefabricated

bar joists, designed to conform to specific load

requirements, are obtainable from commercial

companies. Other long-span construction methods

involve several different types of framing systems,

which include steel arches, cable-hung frames, and

other types of systems. These methods are beyond the

scope of this TRAMAN.

Figure 1-40.—Typical steel trusses.

1-20