specifications, and for establishing safe handling

procedures.

Bituminous materials are manufactured to meet

specifications established by the federal government,

American Association of State Highway and

Transportation Oficials (AASHTO), and American

Society for Testing and Materials (ASTM). These

specifications define the extreme limits permitted in the

manufacture of the material and assure the user that the

material will possess definite characteristics and fulfill

the project requirements. Some of the different tests the

EA should be able to perform in the laboratory are

discussed below. Other tests that you are less likely to

perform, but should be aware of, are discussed in

NAVFAC MO-330.

Identification Tests

The laboratory identification kit for bitumens

consists of a number of jars containing samples of

bitumens in all the recognized categories. To use this kit,

you must bring an unidentified sample to approximately

the same temperature as the kit samples, and then,

following instructions that come with the kit, make

identification on the basis of similarity of color, feel,

consistency, and odor.

A bituminous material suitable for use in pavement

has a considerably higher ductility (which may be

roughly defined as stretchability) than one that is

suitable only for use as a waterproofer, roofing binder,

or crack filler. Any crude method of determining the

presence or absence of ductility (such as stretching the

material like an elastic) will indicate whether or not the

unidentified samples lies somewhere in the category of

pavement material.

Distillation Test

If the unknown bitumen proves to be an asphalt and

has an odor that indicates the presence of a distillate

(such as the odor of kerosene or naphtha), a distillation

test will indicate the character and approximate grade.

In making this test, bear in mind that the basic material

for RC and MC is asphaltic cement; that is, penetration

asphalt. The basis for SC, however, is not asphaltic

cement, but an asphalt residual oil too fluid to be

penetration-tested for grade.

RC, MC, and SC all contain a distillate; that is, a

volatile liquid that evaporates during the curing process.

For RC and MC, the distillate is highly volatile and

evaporates quickly; for SC, it is considerably less

volatile.

The grade of RC, MC, or SC increases with the ratio

of bitumen to distillate. Obviously, the higher the

percentage of bitumen, the more solid the material will

be, and, therefore, the higher the grade. For RC and MC,

the percentage of bitumen for a given grade is the same,

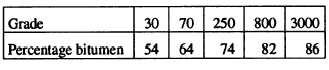

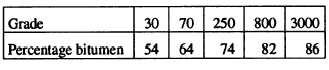

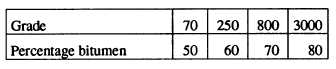

as shown in the following example:

These figures mean that for MC-30, for example,

the percentage of bitumen is 54—the percentage of

distillate being determinable, of course, by subtracting

the percentage of bitumen from 100.

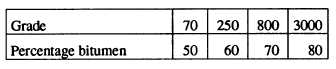

For SC the bitumen percentages are somewhat

lower as follows:

From the distillation test, you can determine the

bitumen percentage and whether the material is SC, RC,

or MC. If it turns out to be RC or MC, the speed with

which the distillate evaporates during the test (naphtha

or gasoline will evaporate much more rapidly than

kerosene) will indicate whether it is RC or MC.

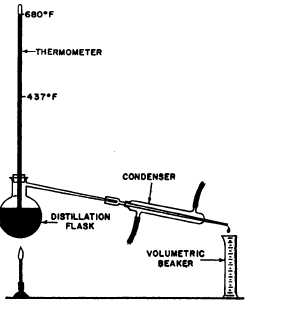

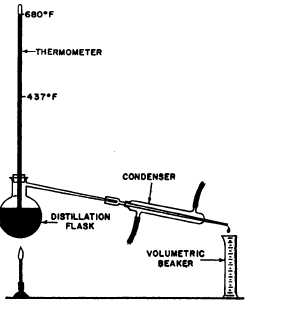

Figure 13-30 shows the apparatus used in

distillation testing. A measured quantity (measured by

volume) of the bitumen is placed in a distillation flask

Figure 13-30.-Apparatus for distillation testing.

13-43