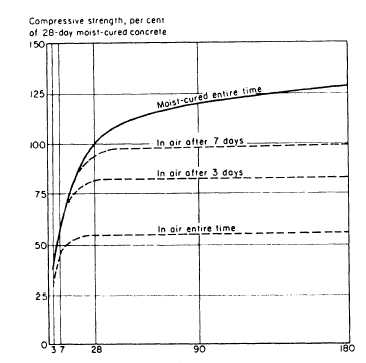

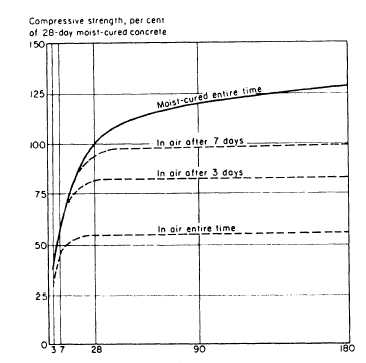

Figure 13-20.—Increase of concrete compressive strenth with

curing age.

figure 13-20. Note the long-time gain in strength that

occurs when proper temperature and moisture

conditions are maintained.

CONCRETE TESTING

Several tests, such as slump, air content, and weight

determination, are necessary to determine the quality of

freshly mixed concrete. In addition, strengths tests are

needed to determine whether a hardened concrete

satisfies specified strength requirements. This section

briefly discusses those tests.

Slump Test

As you know, the measure of the workability or

consistency of a concrete mix is its slump. With too little

slump, the mixture may be too difficult to work into the

forms and around the reinforcing steel. On the other

hand, with too much slump, the concrete ingredients

may segregate and excessive bleeding or migration of

water to the top surface of the freshly placed concrete

may occur. Excess bleeding increases the water-cement

ratio near the top surface of the concrete and results in

a weak top layer with poor durability.

To determine whether a freshly mixed concrete

satisfies the specified requirements for slump, you must

perform a slump test. By now, you should be thoroughly

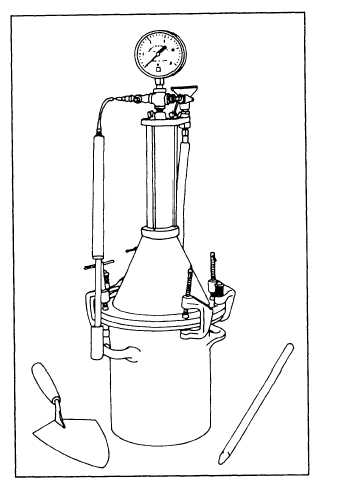

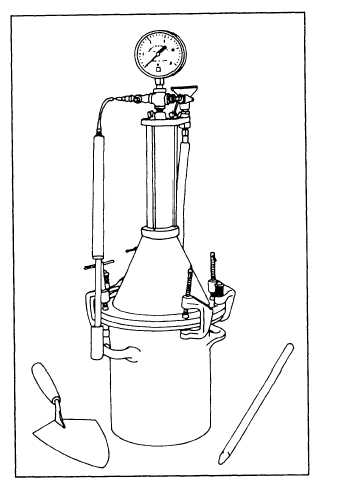

Figure 13-21.—Apparatus for air-content test.

familiar with the procedures of slump testing. If not, you

should review the discussion of slump testing that is in

the EA3 TRAMAN.

Air-Content Test (ASTM C 231)

An air-entraining admixture is added to the concrete

mix so that enough air will be entrained to improve

workability and durability of the mixture, but not

enough to reduce strength substantially. Air-entraining

cements may also be available for use in some military

situations. The desired amount of air is generally from

4.0 to 7.5 percent of the total mix.

The equipment for determining the percentage of

entrained air is included in the boxed test kit. The basic

tool is the pressure type of indicator, as illustrated in

figure 13-21. The equipment furnished in these kits

varies with the manufacturers. Each kit contains the

complete equipment for conducting the test, including a

detailed instruction pamphlet and the calibration

procedure for the particular meter. Before the air content

of a concrete mixture can be determined, the

13-29