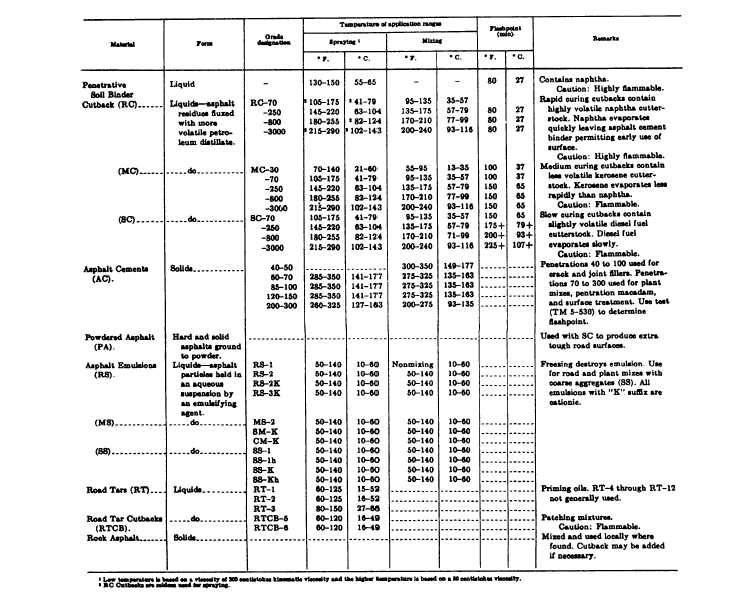

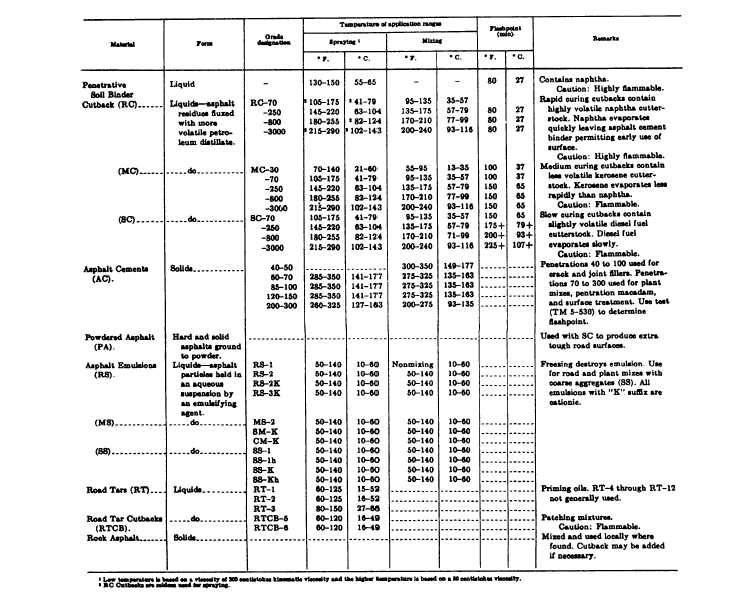

Table 13-6.-Characteristics of Bituminous Materials

cutback asphalt, but differs in many specific properties.

It is used as a soil binder and dust palliative.

EMULSIONS.– Emulsification is the third process

in which asphalt is liquified. In the emulsification

process, hot asphalt cement is mechanically separated

into minute globules and is dispersed in water that is

treated with a small quantity of an emulsifying agent,

such as soap, colloidal clay, or one of numerous other

organic agents. The rate at which the asphalt globules

separate from the water is called the breaking or setting

time. This rate is generally dependent upon the

emulsifier used and the proportion of water to asphalt.

Based in the breaking time, emulsions are described

as rapid setting (RS), medium setting (MS), and slow

setting (SS). They are also described by viscosity

numbers (fig. 13-28).

Emulsions are also grouped according to their

ability to mix with damp aggregate. The RS emulsion

breaks so fast that it cannot be mixed; therefore, it is

called a nonmixing emulsion. The MS and SS emulsions

break slowly enough to permit good mixing; that is, each

particle of the aggregate is uniformly coated. Emulsions

may be satisfactorily used as a tack coat for bituminous

pavements.

ROAD TARS.— Tars are products of the

distillation of coal. No natural sources of tar exist. Coal

tar is a general term applied to all varieties of tar

obtained from coal. It is produced by one of several

methods, depending on the desired end product. When

.

13-38

----------

L– .