Step 5. Discharge the dry chemical by squeezing

Step 4. Remove any dry chemical from the

internal threads of the bottle and from the threads of the

the squeeze grip on the nozzle. Hold the nozzle firmly

cap.

and direct the dry chemical at the base of the fire. Use a

wide-sweeping motion from side to side. This will

Step 5.

Replace the fill cap.

apply a dense, wide cloud of dry chemical over the area.

The steps of the procedure you should adhere to

Remember that the 27-pound extinguisher has a 21-foot

when installing a new CO2 cartridge are as follows:

range and the 18-pound extinguisher has a reach of

19 feet.

Step 1. Lift the lever cutter assembly and insert

the locking pin.

Step 6. Be certain that all of the fire in the area in

which you are working is extinguished before you move

Step 2.

Reseal the locking pin and cutter lever.

in farther. If the fire appears to be too large or if there is a

Step 3.

Remove the guard covering the CO2

possibility of being outflanked or surrounded by flames,

cartridge.

attack the fire with the assistance of two or more

Unscrew the expended CO2 cartridge.

Step 4.

personnel using extinguishers.

Step 5. Remove the cap and gasket from a new

Step 7. Do not try to economize on the dry

CO2 cartridge.

chemical. Use as much as necessary (and as many

extinguishers as necessary) to extinguish the fire

Step 6. Thread the new cartridge, which has

completely.

left-hand threads, into the fitting of the cutter assembly.

Step 8.

Always back up dry chemical with water

Replace the CO2 cartridge guard.

Step 7.

or foam.

AQUEOUS FILM-FORMING FOAM FIRE

Step 9. After a dry chemical extinguisher has

EXTINGUISHER

been used, invert the cylinder, squeeze the discharge

Portable aqueous film-forming foam (AFFF) fire

lever of the nozzle, and tap the nozzle on the deck. This

extinguishers are used to provide a vapor seal over a

will release any pressure left in the cylinder and

small fuel spill, extinguish small class BRAVO fires

cartridge and any dry chemical left in the hose and

(such as deep fat fryers), and for standing fire watch

nozzle. By inverting the cylinder, you prevent further

during hotwork.

discharge of dry chemical and conserve the powder.

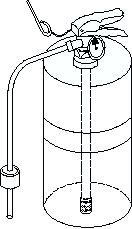

The portable AFFF fire extinguisher (fig. 5-2) is a

Make sure that dry chemical does not remain in the hose

stainless steel cylinder containing 2 1/2 gallons of

and nozzle; it will cake up and clog them.

p r e m i x e d A F F F c o n c e n t r a t e a n d w a t e r. I t i s

The steps of the procedure you should adhere to

pressurized with air to 100 psi at 70 and weighs

when recharging a dry chemical extinguisher are as

approximately 28 pounds when fully charged. The

follows:

mixture will expand about 6.5 to 1 and will produce

about 16 gallons of foam. The AFFF extinguisher has a

Step 1. Invert the extinguisher and tap the side of

55-65 second continuous discharge time and an initial

the cylinder with the nozzle to knock down any loose

range of 15 feet, which decreases during discharge.

dry chemical. Then bleed off the pressure.

Step 2.

Remove the fill cap.

WARNING

D o N OT l e a n o v e r t h e t o p o f t h e

extinguisher when you remove the fill cap. If

dry chemical splashes on you, it could cause

severe injury to your skin and eyes.

Step 3. Fill the cylinder with dry chemical only to

the bend in the tube. The extra space allows the powder to

DCf0502

be aerated when the cylinder is pressurized. This ensures

Figure 5-2. Portable aqueous film-forming foam fire

that the powder will not be caked when it is applied.

extinguisher.

5-2