unit is maintained according to the Planned

foreign matter into the transfer unit or into the cylinder

Maintenance System (PMS) and with the

being recharged. Do not open the supply cylinder valve.

manufacturer's instructions.

Step 3. Place the empty cylinder on the scale. If a

rack is used, invert the cylinder in a near vertical

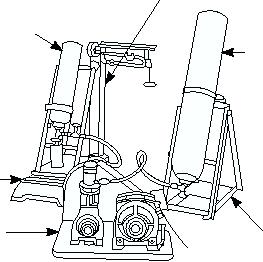

RACK FOR

position; otherwise set it horizontally.

INVERTING

PORTABLES

Step 4. Connect the pump outlet hose to the

PORTABLE 15 LB

CYLINDER BEING

STANDARD

recharging adapter. The pump outlet hose is fitted with a

RECHARGED

COMMERCIAL

50 LB CYLINDER

shutoff valve. Check all connections to ensure that they

are correct and secure. All connections should be made

with a wrench, using a slow, steady pulling motion. Do

not jerk the wrench and do not hit it with a hammer.

Step 5. After making certain that the shutoff

valve in the pump outlet hose is tightly closed and the

SCALES

valve of the cylinder to be recharged is in the OPEN

position, completely open the valve of the supply

cylinder.

MOTOR-DRIVEN

PUMP

TILTING

Step 6. Balance the scale and note the weight of

RACK

the cylinder being recharged. When using beam-type

DCf0504

scales, set the scale to the weight of the empty cylinder

Figure 5-4. CO2 transfer unit.

plus the desired charge.

Step 7. Open the shutoff valve in the pump outlet

As a Damage Controlman, you may be required to

hose and allow the CO2 in the supply cylinder to flow

clean, inspect, and lubricate the CO2 transfer unit. You

under its own pressure into the cylinder being

may also be involved in replacing components of the

recharged.

unit, testing as required, and in recharging CO2 bottles.

Step 8. When the weight of the cylinder being

Before operating the CO2 transfer unit, you must

recharged stops increasing, the CO2 has stopped

ensure the switch on the side of the motor is in the OFF

flowing under its own pressure. At this point, start the

position. Check the circuit from which the motor is to

transfer unit and watch the scale carefully. The transfer

pump should be started only when all valves are verified

be energized and make certain it is the same as that

correctly aligned; otherwise, overpressurization in the

indicated in the nameplate on top of the motor. If a

transfer system may rupture the neoprene seal.

220-volt, 60-cycle, single-phase current is available,

the hookup of the motor leads should be arranged so

CAUTION

the motor will operate in this circuit. A wiring diagram

for operation on 220 volts is located on the motor

Do not close the valve of the cylinder

nameplate. Check all CO2 connections on both the

being recharged or the shutoff valve in the

inlet hose and outlet hose. (The 6-foot-long hose is the

pump outlet hose while the transfer unit is

pumping.

pump outlet hose.) Make certain that all connections

between the fittings are tight. This is very important,

Step 9. When the full capacity of the cylinder

because the CO2 is stored under high pressure.

being recharged has been reached, perform the

The steps of the procedure you should adhere to

following operations in rapid succession.

when operating the CO2 transfer unit are as follows:

a.

Stop the transfer unit motor.

Step 1. With the transfer unit, scale, and tilt racks

b. Tightly close the shutoff valve in the

in place, check the supply cylinder. Use only the

pump outlet hose.

50-pound commercial cylinders. The cylinder shall be

c.

Close the valve of the cylinder being

inverted.

recharged.

Step 2. Connect the pump inlet hose to the supply

Step 10. Disconnect the hose from the cylinder

cylinder outlet. The connection adapter of the hose is

being recharged. Do this very slowly to allow the escape

fitted with a screen to prevent the entrance of any

5-4