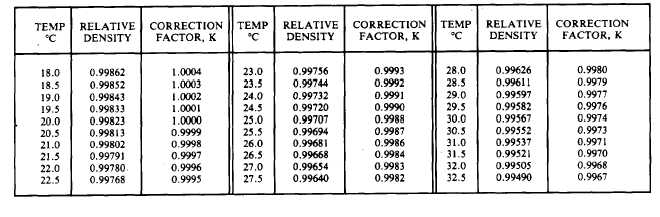

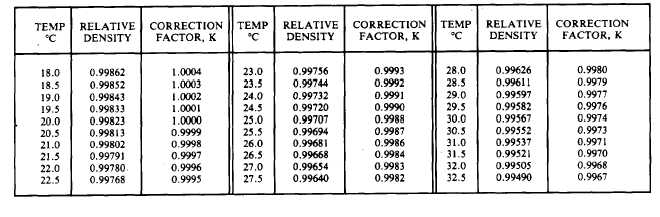

Table 15-3.-Relative Density of Water and Correction Factor (K) at Various Temperatures

boiling may cause material to be boiled out of

Weight of the flask filled with water

the flask.

7. After all air has been exhausted, and the

flask and contents have cooled, add more

de-aired, distilled water until the flask is filled

to the ring marked on the neck. To ensure

all air is exhausted, a second boiling may be

necessary.

8. Next, dry the outside of the flask and

any moisture above the water surface inside the

flask.

9. Weigh the flask and contents to the

nearest 0.01 g, and record the information in

block 6j (fig. 15-33). This is Wbws.

10. Immediately after weighing, stir the

suspension to assure even temperature distribu-

tion. Immerse a thermometer to mid-depth of the

flask, and read the temperature of the soil-water

suspension. Record this temperature in block 6C

(fig. 15-33).

11. Finally, with the data entered on the data

sheet, compute the specific gravity using the

following formula:

only, at test temperature. You can

get this value from a calibration

curve, or table, previously prepared

for the flask used in the test.

Weight of the flask, water, and

sample at test temperature

Bulk and Apparent Specific Gravity

The following discussion applies to determina-

tion of bulk and apparent specific gravity.

Bulk specific gravity is usually determined for

the coarser materials that are retained on a

No. 4 sieve. Large stones may be determined

individually.

SAMPLE PREPARATION.— Separate the

sample on a No. 4 sieve, and use the material re-

tained on that sieve for the test. Approximately

2 kg is required. Ensure the sample is a represen-

tative sample.

In preparing the sample, first wash the

material to remove dust and coatings. Then

immerse and soak the sample in water for 24 hr.

Just before making the test, dry the sample to-a

saturated-surface-dry condition. Do this by

where:

w,

=

K

=

rolling the sample in art absorbent cloth to remove

excess surface water. You may wipe large particles

individually. When saturated-surface-dry, the sur-

Dry weight of the sample

face may still appear damp. Take care to avoid

excessive evaporation during the surface drying.

Correction factor based on the

APPARATUS.— Apparatus for the test is as

density of water at 20°C. You can get

follows:

this factor from table 15-3 by select-

Balance, 5 kg or larger, sensitive to 0.1 g

ing the correction factor that cor-

Wire mesh basket, approximately 8 in. in

responds to the temperature obtained

diameter and 8 in. high; 2-mm (No. 6) or finer

in Step 10, above.

mesh

15-28