for connecting rigid metal conduit are shown in

figure 9-15, view A. The use of rigid conduit

involves a good deal of cutting, bending, and

threading of lengths. An ordinary hacksaw or

special wheel pipe cutter is used for cutting, while

a ratchet type of mechanical die is used for thread-

cutting conduit pipes. Bending of pipes can be

undertaken both manually, using a bending tool

commonly called a hickey, and hydraulically. A

hydraulic bender is recommended for making

smooth and accurate bends.

CONDULETS (fig. 9-15, view A (2)) are a

convenient way of making bends, especially in

conduit that will be exposed to the elements. They

are heavily used on sharp corners and also to

reduce the number of bends made in a run of

conduit.

Another type of rigid conduit approved for

use by NAVFAC is the polyvinyl chloride (PVC)

pipe. This now popular plastic conduit is specially

suitable for use in areas where corrosion of metal

conduits has been a problem. Some of the

advantages of PVC conduit are as follows: light

handling weight,

ease of installation, and

leakproof joints.

This conduit is primarily

intended for underground wire and cable raceway

use and is made in two forms. Type I is designed

for concrete encasement, and Type II is designed

for direct earth burial. Rigid plastic conduit and

fittings are joined together by a solvent-type

adhesive welding process. It also comes in sizes

of 1/2 to 6 in. in diameter. PVC fittings are also

available from the manufacturer. (For more

information on PVC fittings, refer to Article 370

of the NEC®.)

THIN-WALL CONDUIT.— Electric metallic

tubing (EMT) or thin-wall conduit, as it is better

known, is a type of conduit with a wall thickness

quite a bit less than the rigid conduit. It is made

in sizes from 1/2 to 2 in. in diameter. Thin-wall

conduit cannot be threaded; therefore, special

types of fittings (fig. 9-15, view B) must be used

for connecting pipe to pipe to boxes.

FLEXIBLE CONDUIT.— Flexible conduit

(fig. 9-15, view C), also called Greenfield, is a

spirally wrapped metal band wound upon itself

and interlocking in such a manner as to provide

a round cross section of high mechanical strength

and flexibility. It is used where rigid conduit

would not be feasible to install and requires no

elbow fittings. It is made in sizes from 1/2 to

3 in. in diameter. Greenfield is available in two

types: the plain or standard unfinished-metal type

and a moisture-resistant type called sealtite, which

has a plastic or latex jacket. The moisture-resistant

type is not intended for general use but only

for connecting motors or portable equipment in

damp or wet locations and where flexibility of

connections is desired.

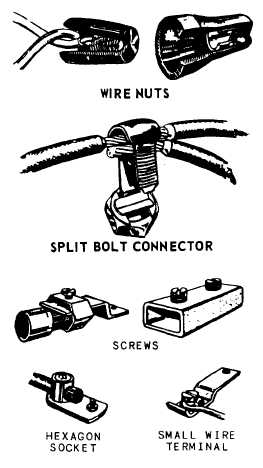

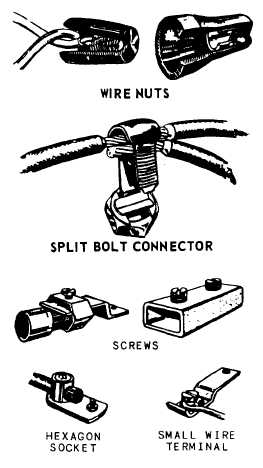

Wire Connectors

Figure 9-16 shows various types of connectors

that are used to join or splice conductors. The type

used will depend on the type of installation and

the wire size. Most connectors operate on the

same principle, that of gripping or pressing the

conductors together. WIRE NUTS are used

extensively for connecting insulated single

conductors installed inside of buildings.

Outlet Boxes

OUTLET BOXES bind together the elements

of a conduit or cable system in a continuous

Figure 9-16.-Types of cable and wire connectors.

9-12