are set according to the proportions obtained in the

computation of the final trial blend.

Aggregate Blending Limits

Figure 17-7 is an aggregate grading chart (DD Form

1207), showing the specification limits for the mix and

the gradation of the blend when mixed in the proportions

shown in figure 17-6A, trial No. 1.

Specify Gravity of Bituminous Mix

Components

A specific gravity data sheet is shown in figure 17-8

(DD Form 1216). This form is used for computing the

specific gravity of all the bituminous mix components.

If more aggregate fractions are used than are provided

for on the form, additional forms may be used.

Procedures for performing these tests are discussed in

chapter 13 of this TRAMAN.

Marshall Stability Computations

DD Form 1218 (figs. 17-9A and 17-9B) is a data

and computation sheet used in the Marshall stability test.

The specific gravity values of the aggregates and the

aggregate fraction percentages from the trial blending

furnish the information to compute the fractional

weights and to prepare the test specimens. Record the

measurements made on the test specimens in the upper

right-hand corner of the form. Determine, as described

in chapter 13 of this TRAMAN, the stability, flow, unit

weight of total mix, and percentage of voids filled with

binder to complete the form.

Marshall Method Computations

Transfer the values from DD Form 1218 (figs.

17-9A and 17-9B) for each binder content computation

to DD Form 1219 (fig. 17-10). Each graph on the form

represents a different test property. Plot the values for

each property on their respective graph using the binder

contents as ordinates. Draw a smooth curve through the

plotted points.

Marshall Test Criteria

Table 17-7 lists the criteria for determining

optimum asphalt content (OAC). For each test property,

you should consider the type of mix to be used and the

expected load. The optimum bitumen content for each

property is designated as a definite point on the curve

for that property. The bitumen content percentages (one

for each property) are averaged, and the average is used

to read the corresponding value of each test property.

The value, as determined, should be referred to the

criteria portion of table 17-7 to see if it is within the

permissible limits so that the mix will perform

satisfactorily.

Test Variation for Aggregates with

10 Percent or More Larger Than

1-Inch Maximum Size

The procedure described in the Marshall method

and the examples as given in the preceding paragraphs

are applicable to hot-mix design where the amount of

aggregate larger than the 1-inch sieve is less than 10

percent of the total. When the larger than (plus) 1-inch

material exceeds 10 percent of the total, the following

variations are made in the procedure:

1. Mix bitumen at the selected content with the

entire aggregate, including the plus 1-inch portion.

2. Pass the mixed hot batch through a 1-inch sieve.

Discard the plus 1-inch portion.

3. Make compacted specimens from the portion

that passes the 1-inch sieve and perform the Marshall

test, except do not calculate the voids of the compacted

specimens at this time.

4. Determine the bulk specific gravity of the plus

1-inch aggregate, and, with the specific gravity of the

compacted specimens, compute the adjusted specific

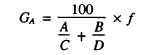

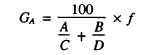

gravity (GA) as follows:

where:

A

= weight of dry, plus 1-inch material

expressed as a percentage of the total batch

weight (bitumen plus aggregate)

B

= portion of total batch remaining after the

dry, plus 1-inch portion is removed

(100%-A%)

C =

bulk specific gravity of plus 1-inch

aggregate

D =

actual specific gravity of compacted

specimen

f

= empirical factor = 0.995

17-20