CHAPTER 5

DECK SEAMANSHIP

LEARNING OBJECTIVES

Upon completing this chapter, you should be able to do the following:

1. Describe the most common deck fittings used on board ship.

2. Describe the approved rigging and procedures for going aloft and working over

the side.

3. Explain the safety requirements for going aloft and working over the side.

4. Describe the use and care of canvas and leather products on board ship. Explain

how to sew the different types of stitches that are common to deck force duties.

5. Explain the purpose of underway replenishment and identify the basic rigs

associated with underway replenishment.

DECK FITTINGS

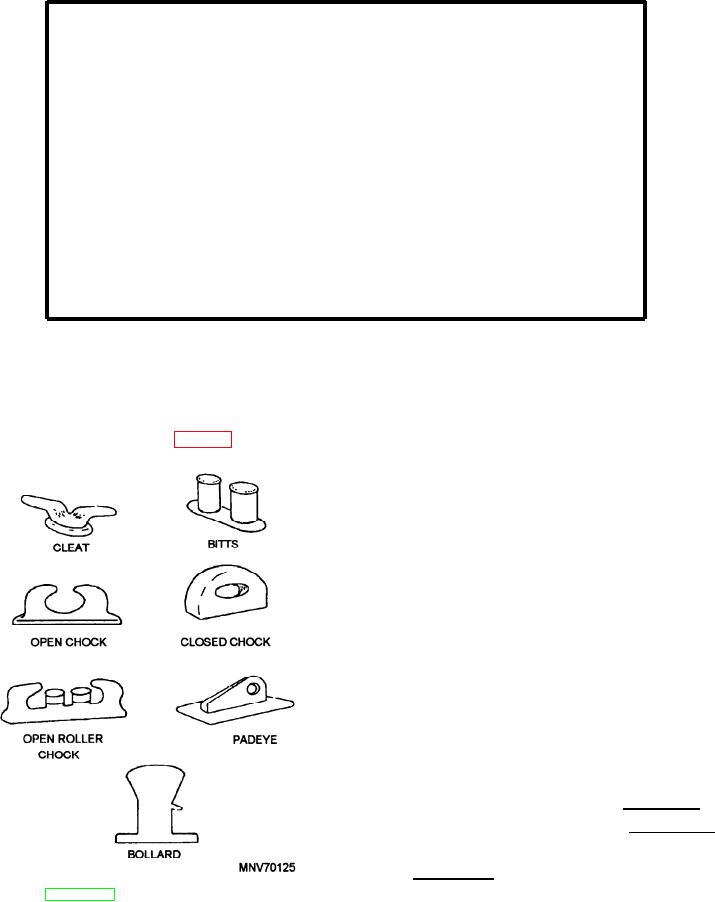

CLEAT

Deck fittings are devices attached to the hull that

A cleat consists of an in-line pair of projecting horns

assist in handling the ship. The most common fittings

and is used for belaying a line.

are found around the weather decks. A brief description

BITTS

of some common deck fittings (fig. 5-1) follows.

Bitts are heavy vertical cylinders, usually arranged

in pairs, that are used for making fast lines led through

chocks. The upper end of a bitt is either larger than the

lower end or is fitted with a lip to keep the lines from

slipping off accidentally. Since bitts take very heavy

loads, extra frames are worked into their foundations to

distribute the strain. Usually, there is a set of bitts

forward and aft of each chock. When constructed in

pairs, each bitt is sometimes called a barrel.

CHOCK

A chock is a heavy fitting with smooth surfaces

through which mooring lines are led. Mooring lines are

run from bitts on deck through chocks to bollards on a

pier when the ship is moored. There are three types of

chocks: open, closed, and roller. An open chock is a

mooring chock that is open at the top. A closed chock is

a mooring chock closed by an arch of metal across the

top. A roller chock is a mooring chock that contains a

roller for reducing friction.

Figure 5-1.--Various deck fittings.

5-1