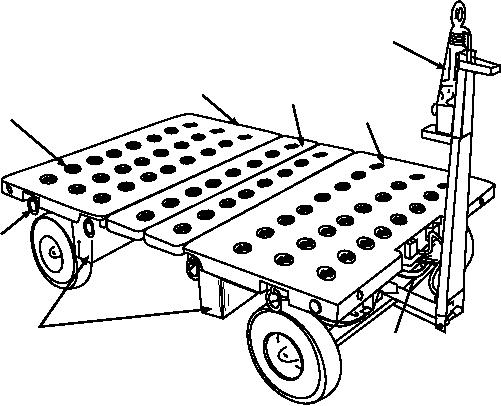

TOWBAR

HINGED

AFT DECK

DECK FORWARD

DECK

TIEDOWNS (64)

TIEDOWN

RINGS (8)

TOOL BOX, SIDE

HANDBRAKE

MN020014

Figure 2-14.--Aero 51B munitions trailer.

the insertion of ball-lock pins. The jacks are operated

an interconnecting electrical harness) are stored in

simultaneously to maintain the necessary length of the

toolboxes mounted underneath the forward and aft

legs of the A-frame at any given time, thereby ensuring

sections of the bed. The center section of the bed is

maximum gantry stability. When the A-frame is within

hinged and can be opened to provide a hatchway across

approximately 4 inches of its desired height, the

the full width of the trailer. Hinged bed panels have

ball-lock pins are removed, allowing the spring-loaded

double rails with holes at intervals to provide a

bolts to press against the telescoping legs. The

mounting base for chocks and roller adapters.

spring-loaded bolts snap into their respective locating

The Aero 51B trailer has a capacity of 8,500

holes when the desired height is reached.

pounds and can be towed in trains of not more than

Removal of a quick-release pin from the sliding

three. Maximum towing speed of one trailer is 20 miles

tube that forms the base of the A-frame permits the

per hour (mph); however, if more than one trailer is

frame to spread to any one of four positions.

being towed, the maximum speed is 10 mph.

Reinsertion of the quick-release pin maintains the tube

in a fixed position. The four 8-inch casters permit easy

GANTRY A-FRAME

maneuvering of the entire structure either indoors or

outdoors. The hoists can be positioned anywhere along

The gantry A-frame is used for suspending one

the desired height of the I-beam. The trolley wheels

portion of a mine when marrying to another. It has two

travel on its bottom flange.

trolleys and two air or chain hoists suspended from a

15-foot I-beam, supported at each end by a steel

The safe working load of the gantry A-frame, as

shown in figure 2-15, is either 3,000 or 4,000 pounds,

A-frame. The working height of the gantry is

d e p e n d i n g o n t h e h o i s t s u s e d . H ow ev e r, t h e

adjustable between approximate heights from 10 to 17

4,000-pound capacity must NEVER be exceeded.

feet by the operation of four independent

spring-loaded bolts and jacks attached to the A-frame

BOMB ASSEMBLY STAND

legs. The spring-loaded bolts seat into located holes in

the telescoping legs of the A-frame.

The bomb assembly stand provides a working

Adjusting the height of the A-frame requires first

height platform in magazine or bomb assembly areas

that each jack be wound tautly to assure support of each

upon which bombs of various weights and sizes can be

leg. Then the four spring-loaded bolts are pulled out of

assembled. The stand, as shown in figure 2-16, consists

of three table assemblies and four tray assemblies. The

their respective locating holes and held tensioned by

2-21