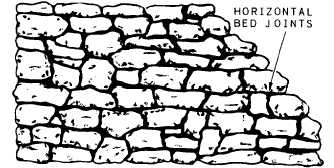

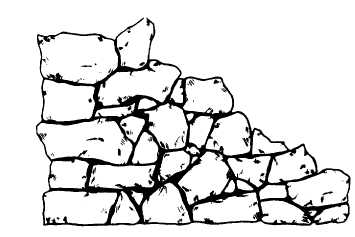

Figure 7-47.-Random rubble stone masonry.

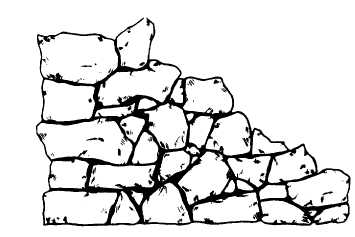

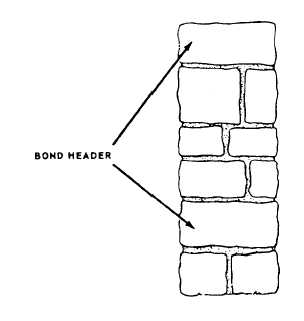

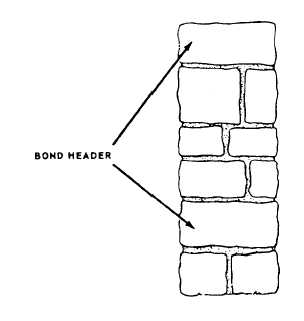

Figure 7-48.-Layers of bond stones in random stone

masonry.

stones in courses, as shown in figure 7-47. Each

layer must contain bonding stones that extend

through the wall, as shown in figure 7-48. This

produces a wall that is well tied together. The bed

joints should be horizontal for stability, but the

“builds” or head joints may run in any direction.

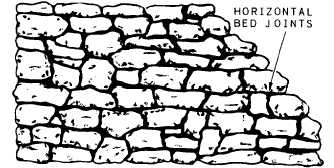

Coursed rubble consists of roughly squared

stones assembled in such a manner as to produce

approximately continuous horizontal bed joints,

as shown in figure 7-49.

The stone for use in stone masonry should be

strong, durable, and cheap. Durability and

strength depend upon the chemical composition

and physical structure of the stone. Some of the

Figure 7-49.-Coursed rubble masonry.

more commonly found stones that are suitable are

limestone, sandstone, granite, and slate. Un-

squared stones obtained from nearby ledges or

quarries or even fieldstone maybe used. The size

of the stone should be such that two people can

easily handle it. A variety of sizes is necessary to

avoid using large quantities of mortar.

The mortar for use in stone masonry may be

composed of portland cement and sand in the

proportions of one part cement to three parts sand

by volume. Such mortar shrinks excessively and

does not work well with the trowel. A better

mortar to use is portland cement-lime mortar.

Mortar made with ordinary portland cement will

stain most types of stone. If staining must be

prevented, nonstaining white portland cement

should be used in making the mortar. Lime does

not usually stain the stone.

BRICK MASONRY

In brick masonry construction, units of baked

clay or shale of uniform size are laid in courses

with mortar joints to form walls of virtually

unlimited length and height. These units are small

enough to be placed with one hand. Bricks are

kiln-baked from various clay and shale mixtures.

The chemical and physical characteristics of the

ingredients vary considerably; these and the kiln

temperatures combine to produce brick in a

variety of colors and harnesses. In some regions,

pits are opened and found to yield clay or shale

that, when ground and moistened, can be

formed and baked into durable brick; in other

regions, clays or shales from several pits must be

mixed.

The dimensions of a U.S. standard building

brick are 2 1/4 by 3 3/4 by 8. The actual

dimensions of brick may vary a little because of

shrinkage during burning.

7-30