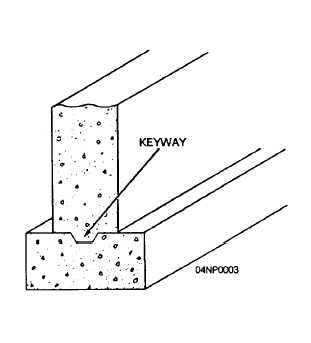

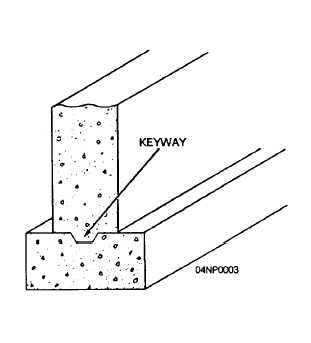

Figure 7-22.-Use of a contraction Joint.

incident to shrinkage of the concrete. A typical dummy

contraction joint (fig. 7-22) is usually formed by cutting

a depth of one third to one fourth the thickness of the

section. Some contracting joints are made with no filler

or with a thin coat of paraffii or asphalt and/or other

materials to break the bond. Depending on the extent

of local temperature, joints in reinforced concrete slabs

may be placed at 15-to 25-ft intervals in each direction.

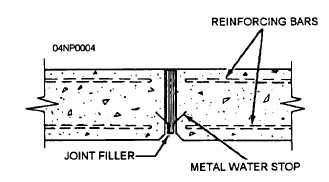

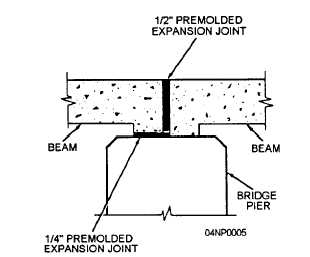

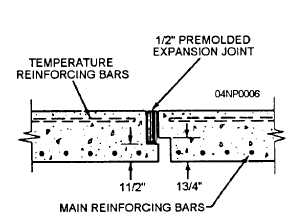

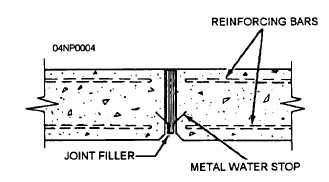

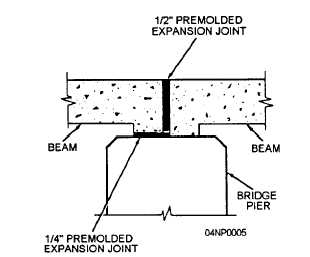

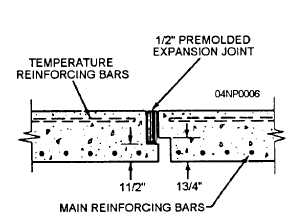

Expansion Joints

Wherever expansion might cause a concrete slab to

buckle because of temperature change, expansion joints

(also called isolation joints) are required. An expansion

joint is used with a pre-molded cork or mastic filler to

separate sections from each other, thus allowing room

for expansion if elongation or closing of the joint is

anticipated. Figures 7-23, 7-24, and 7-25 show

Figure 7-23.-Expansion joint for a wall.

Figure 7-24.-Expansion joint for a bridge.

Figure 7-25.-Expansion joint for a floor slab.

expansion joints for a variety of locations. Expansion

joints may be installed every 20 ft.

CONCRETE FORMS

Most structural concrete is made by placing

(also called CASTING) plastic concrete into

7-17