spaces enclosed by previously constructed

FORMS. These forms are usually removed once

the plastic concrete hardens into the shape

outlined by the forms.

Forms for concrete structures must be tight,

rigid, and strong. If the forms are NOT tight, loss

of water and paste may cause sand streaking as

well as weakness to the concrete. The forms must

be strong enough to resist the high pressure

exerted by the concrete.

Form Materials

Undisturbed soil or clay, if sufficiently rigid

and excavated to proper dimensions, maybe used

as EARTH FORMS. Design, specifications, and

construction methods, however, dictate what kind

of form materials are to be used on certain

structures. Wood, plywood, steel, fiber glass, and

other approved materials are commonly used as

form materials. Forms for concrete pavement and

curves should be metal; surfaces exposed to view

in the finished structure and those requiring

special finishes should be wood, plywood, or

other approved material.

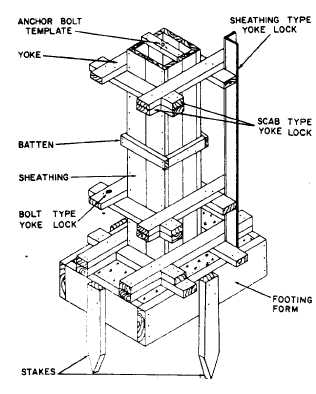

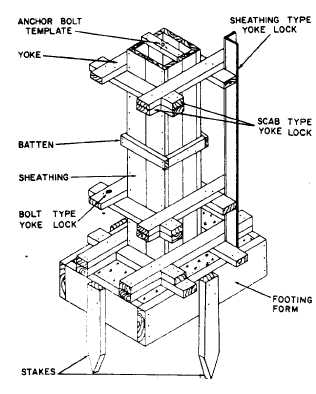

Figure 7-28.-Form for concrete column.

Foundation Forms

Foundation forms may include forms or parts

of forms for column footings, pier footings, and

wall footings. Whenever possible, the earth should

be excavated and the hole used to contain the

foundation of footing forms. In most cases,

FOOTINGS are cast directly against the earth,

and only the sides are molded in forms. In some

cases where there is a firm natural earth surface

that is capable of supporting and molding the

concrete, parts of forms are often omitted.

Figure 7-26 shows a typical large footing form.

Figures 7-27 and 7-28 show typical footing forms

for a concrete pier and a concrete column,

respectively.

Wall Forms

Wall forms are made up of five basic parts.

They are as follows: (1) sheathing, to shape and

retain the concrete until it sets; (2) studs, to form

a framework and support the sheathing; (3) wales,

to keep the form aligned and support the studs;

(4) braces, to hold the forms erect under lateral

pressure; and (5) ties and spreaders or tie-spreader

units, to hold the sides of the forms at the

correct spacing (fig. 7-29).

Wall forms may be built in place or pre-

fabricated, depending on the shape and the

desirability for reuse.

Wall forms are usually reinforced against

displacement by the use of TIES. Two types of

Figure 7-29.-Parts of a typical wall form.

7-19