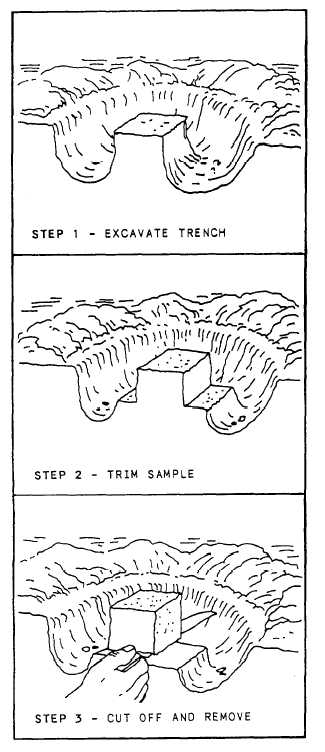

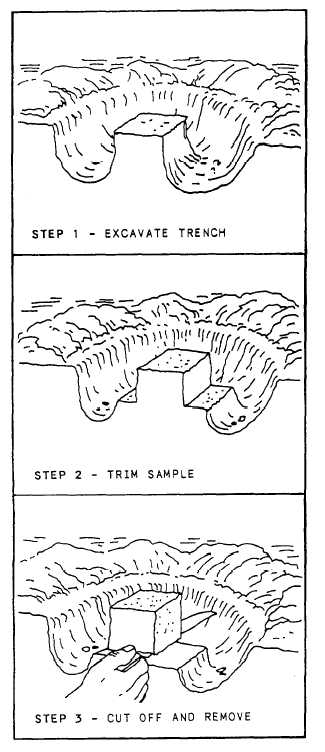

Figure 15-9.-Taking a chunk sample from a level surface.

Figure 15-9 shows the process of taking

a chunk sample from a level surface, such

as a subgrade or the bottom of a test pit.

After smoothing the ground surface and mark-

ing the outline of the chunk, the first step

is to excavate a trench around the chunk.

Then deepen the excavation and trim the sides

of the chunk with a knife. Finally, using a

knife, trowel, or hacksaw blade, cut off the chunk

at the bottom and carefully remove it from the

hole.

To take a chunk. from the vertical face

of a test pit or trench, as shown in fig-

ure 15-10, smooth the surface of the face

and mark the chunk outline. Then excavate

the soil from the top, sides, and back of

the chunk. After shaping the chunk with

a knife, cut it off and carefully remove

it.

After removing the chunk sample from

the hole, you need to seal it. One method

is to apply three coats of melted paraffin,

as shown in figure 15-11. Each coat is al-

lowed to cool and become firm before the

next coat is applied. This gives adequate

protection for strong samples that will be

used within a few days. When the samples

are weak or may not be used within a

few days, wrap them with cheesecloth or

other soft cloth and seal them with paraf-

fin (fig. 15-12). If cloth is not available,

you can reinforce the sample with several

loops of friction tape or twine. Then apply

three coats of paraffin. Take extra precaution in

these operations so that the sample is not

damaged.

Another method is to dip the entire sam-

ple in melted paraffin after the first brush

coat is applied and the sample is wrapped

(fig. 15-13). This requires a larger container

and more paraffin. However; this method pro-

vides a more uniform coating that, by repeated

dippings, can be built up to 1/8 in. or more in

thickness.

When samples are to shipped, as from

a construction battalion’s remote detail site

to the battalion’s main body site, additional

protection is required. This can be accom-

plished by applying many coats of paraf-

fin or by placing the chunk in a small

15-12