Wedges

SHORE

Wedges should be of softwood, preferably fir or

yellow pine. They should be cut with a coarse saw and

left rough and unpainted. This allows the wedges to

SHOLE

absorb water and hold better than if they are smoothed

FILLER

or painted. A few hardwood wedges should be kept on

hand for special uses, since they resist crushing better.

DCf0809

However, hardwood wedges cannot be used for all

Figure 8-9. Use of a shole.

shoring because they have a tendency to work loose.

When hardwood wedges are used, they must be

Strongbacks

checked frequently.

All or part of an ordinary shore may be used to

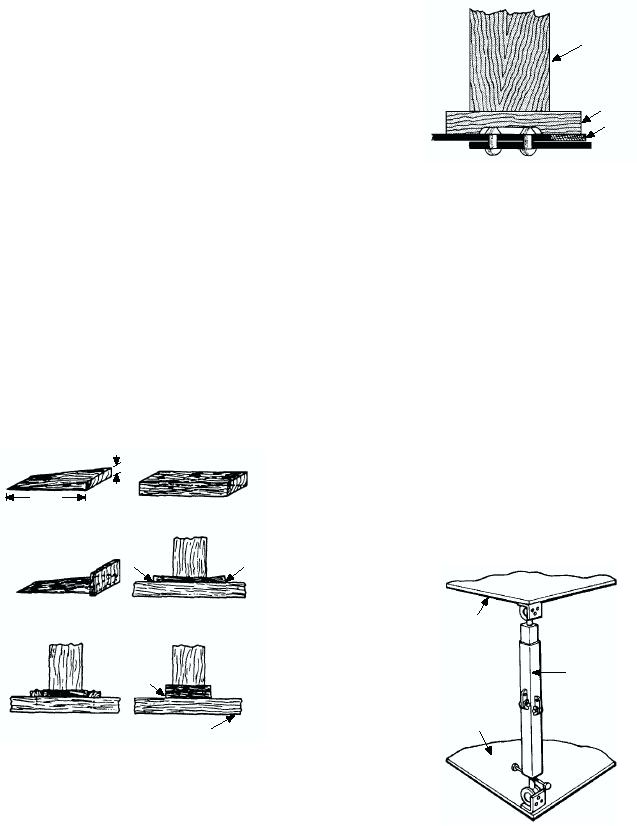

Wedges should be approximately the same width

make a strongback. Shoring scraps should be kept for

as the shores with which they are used. They may be

use as strongbacks and short shores. Heavy planks,

made with various angles at the leading edge, but a

steel bars, angle irons, and pipe can also be used as

blunt wedge will not hold as well as a sharp one. A

strongbacks (fig. 8-6).

wedge should be about six times as long as it is thick.

Metal Shores

Thus a wedge to be used with a shore that is 4 by 4

Several types of telescopic steel shores are used to

inches should be about 4 inches wide, 2 inches thick,

make temporary repairs and some may be used for

and 12 inches long. Figure 8-8 shows some wedges and

immediate repairs. The metal shores normally will

shows how they are used.

have pins or locking devices and are fitted with a

hinged shoe at each end. The pins or locking devices

are used to adjust the length of the shore. The hinged

shoe may be easily adjusted to any angle and then

X

5 TO 6X

welded in place. The newer types of metal shores

2 WEDGES FROM

TAPER OF WEDGE

SQUARE BLOCK

(fig. 8-10) are also fitted with screw jacks or swivel

(ball-and-socket) bases.

USE BLOCK FOR DRIVING

DRIVE FROM BOTH

SIDES UNIFORMLY

OVERHEAD

NEVER USE

NO!

MORE THAN

TWO WEDGES

STEEL

NOT

SHORE

THIS

CLEATS PREVENT

USE THICKER

DECK

WEDGE SLIPPAGE

FILLER PIECE

DCf0808

Figure 8-8. Wedges.

Sholes

DCf0810

Figure 8-10. Steel shore supporting overhead deck or load.

Sholes should be made of Douglas fir or yellow

pine planks that are at least 1 inch thick and 8 inches to

The newer steel shores are available in two models

12 inches wide. Nailing cleats across two or more

as follows:

widths of planking can make wider sholes. A single

1. Model 3-5 is adjustable from a minimum of

plank may have to be cleated at the ends to keep it from

3 feet, plus or minus 3 inches, to a maximum of 5 feet,

splitting. Do not fabricate sholes in advance of the

plus or minus 3 inches. It will support a maximum

actual need for them; prefabricated sholes would

vertical load of 20,000 pounds when closed to within

probably not fit where they are needed. The use of a

1 inch of the screw jack. It will support a maximum

shole is shown in figure 8-9.

vertical load of 12,000 pounds when fully extended.

8-9