One maul or sledge

an inboard compartment is flooded, other

compartments will flood if you open doors or hatches

One hammer; a minimum 2 pounds in weight

to get to the actual area of damage. The repair work

One crosscut handsaw for cutting wood

may be hampered by tangled wreckage in the water,

the absence of light, and the difficulties of trying to

The plugs and wedges may be used individually if

keep buoyant repair materials submerged.

they fit the hole. Often however, it is best to use a

combination of conical, square-ended, and

PLUGGING AND PATCHING HOLES

wedge-shaped plugs to make a better fit in the hole.

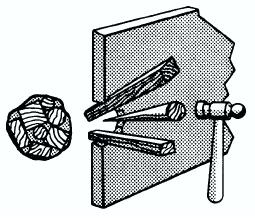

One such combination of plugs is shown in figure 8-2.

The procedures discussed here for plugging and

patching holes are intended for emergency use. They

are temporary repairs that can be done to keep the ship

afloat while it is in action. In most cases, they do not

call for elaborate tools or equipment. They involve

principles that can be applied when using wooden

plugs, prefabricated patches, or other readily

available materials.

The two general methods of making temporary

repairs to a hole in the hull are as follows:

1.

Put something in it.

DCf0802

2.

Put something over it.

Figure 8-2. Combination of plugs used to plug a hole.

In either case, the patches will reduce the area

through which water can enter the ship or through

It is best to wrap each plug with lightweight cloth

which water can pass from one compartment to

before inserting it. The cloth tends to keep the plugs in

another.

place and fills in some of the gaps between the plugs.

In most cases, plugs will not make a watertight fit.

Plugging

However, you can substantially reduce the rate of

leakage by using the plugs and then caulking the

The simplest method of stopping up a fairly small

remaining leaks with rags, oakum, and smaller

hole is to insert some kind of plug. Plugs made of

wedges. Square-ended plugs tend to hold better than

softwood, such as yellow pine or fir, are quite

conical plugs in holes located in plating that is

effective for plugging holes up to about 3 inches by 3

one-fourth of an inch or less in thickness.

inches in size. Sometimes you may use these plugs to

plug larger holes as well.

Most wooden plugs are inserted from the inside of

the ship. When plugging a hole in this manner, you

The items in a plugging kit are as follows:

must contend with the metal edges that are protruding

A c a nva s b a g w i t h a c a r r y i n g s t r a p

inward. You normally will not have this problem

approximately 30 inches deep and 12 inches in

when plugging a hole from the outside of the ship.

diameter

However, plugs on the outside of the ship cannot be

Softwood plugs; a minimum of 10 plugs in

tended easily nor will they hold very well over an

extended period of time. If it is necessary to insert the

various sizes from 1 inch to 10 inches in

plugs from the outside of the hull, fit the inboard ends

diameter

of the plugs with screw eyes. A line running from each

Five pounds of oakum or rags

screw eye and secured to a solid structural member

One hatchet

inside the ship will help to keep the plug in place.

One cold chisel

Patching

One metal caulking iron

Box patches are effective for use over holes that

Wedges made of softwood; a minimum of eight

have jagged edges projecting inboard. View A of

figure 8-3 shows a typical metal box patch; view B

wedges, 2 inches by 4 inches and 12 inches long

8-5