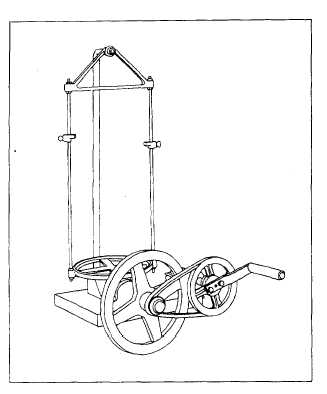

Figure 15-30.-Hand-operated sieve shaker.

The hand-operated shaker is shown in figure

15-30.

SIEVE ANALYSIS, DRY.— The minimum

sample weight required for a sieve analysis is

dependent upon the maximum particle size in the

sample as follows:

Maximum particle size Minimum dry weight

(sieve opening)

of test specimen

3 in.

6,000 g

1 1/2 in.

3,000 g

3/4 in.

1,500 g

3/8 in.

600 g

No. 4

200 g

Samples that contain cohesive soil, which

forms hard lumps, must be prewashed. This pro-

cedure is described later. Other samples are

analyzed DRY by the following procedure:

1. Oven-dry the sample.

2. Break up lumps. For coarse material, use

a rolling pin on a clean, hard, smooth surface.

For fine material, use a mortar and pestle (usually

a part of the laboratory apparatus). Take care not

to crush individual grains. The object is to

separate aggregations of clustering grains.

3. Weigh the sample.

4. Select and weigh the sieves and pan to be

used in the test. The sieve selection varies

according to the type of soil being tested. The

following is a selection commonly used:

3 in. (76.2 mm)

No. 10 (2.00 mm)

1 1/2 in. (38.1 mm) No. 20 (1.21 mm)

1/2 in. (12.7 mm)

No. 40 (0.42) mm

3/8 in. (9.52 mm)

No. 100 (0.149 mm)

No. 4 (4.76 mm)

No. 200 (0.074 mm)

Stack (nest) the sieves one on top of the other

such that the largest sieve is on top. The coarsest

sieve actually recorded is the next above the first

one that retains any material. The weight recorded

as retained on this sieve is 0 g; the weight

recorded as passing it is the total weight of the

sample.

5. Place the sieve pan under the stack of

sieves; place the total sample in the top sieve and

shake. The shaking interval depends on the

amount of fine material. Five minutes is usually

enough for most coarse-grained soils, and 15 min

is enough for most fine-grained soils.

6. Remove the sieves from the shaker. Start-

ing with the first to retain any material, carefully

weigh each sieve with the retained material. Sub-

tract the weight of the sieve from the combined

weight of the sieve and material to determine the

weight of the material retained on each sieve.

Finally, determine the weight of the material that

reached the pan; that is, that passed the No. 200,

or finest, sieve.

Enter the results on a data sheet like the one

shown in figure 15-31. In this analysis, all the

material (359. 1 g) passed the 3/8-in. sieve; none

was retained on this one. The No. 4 retained

51.0 g. This means that 308.1 g (359.1 – 51.0)

passed this sieve. You can see how the weight pass-

ing was determined from the weight retained in

each subsequent case. In column d, the percent

passing is computed for each sieve by multiply-

ing the weight passing by 100 and dividing the

result by the total weight of the sample.

15-22