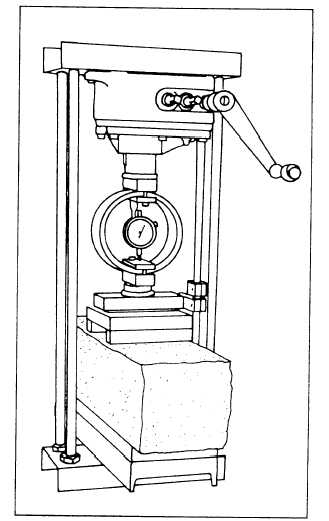

Figure 13-24.—Flexural-strength testing assembly for 6-inch

by 6-inch by 21-inch concrete beam.

For each tested specimen, your test report should

include the identification, diameter, length, maximum

load, compressive strength, irregular fracture or defect

in caps or specimen, and age of specimen at test. Report

the average compressive strength of all cylinders from

the same concrete sample.

Flexural-Strength Test (ASTM C 78)

Flexural strength is the ability to resist an applied

bending force such as encountered by concrete

pavements or other slabs on ground. A determination of

the flexural strength is frequently necessary as part of

the design of concrete mixtures to check compliance

with established specifications or to provide informa-

tion necessary to the design of an engineering structure.

In the flexural-strength test, a test load is applied to

the sides of a test beam. Although the test can be

performed upon beams sawed from existing concrete

structures, it is more commonly performed upon beams

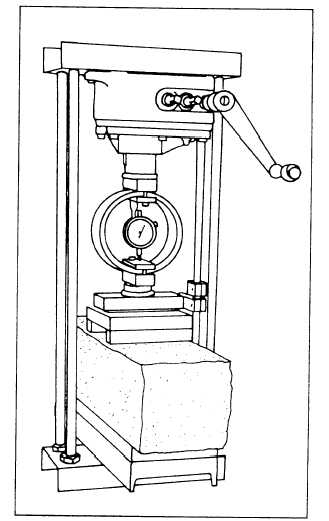

Figure 13-25.—Alternate testing assembly using CBR test

equipment.

that are cast for testing purposes. The standard test beam

measures 6 inches by 6 inches by 21 inches. When

performing the test for mix-design purposes, you will

need at least five beam specimens for each mixture

design being evaluated. Two of the specimens are

broken at 7 days to permit an early evaluation of the mix.

The remaining beams are broken at 28 days. The

procedures for preparing test beams is discussed in the

EA3 TRAMAN. If necessary, you should review those

procedures. The following paragraphs discuss only the

procedures used to perform the test.

When performing the flexural-strength test, you use

a concrete beam tester with third-point loading. An

example of that equipment is illustrated in figure 13-24.

An alternate testing assembly can be made from the

loading frame and certain attachments provided with the

California bearing ratio (CBR) test set, the breaker

(third-point loading), and the 10,000-pound capacity

proving ring. That alternate assembly is shown in figure

13-25.

13-32