The procedures for conducting the flexural-strength

test are as follows:

1. Assemble the loading device, as shown in figure

13-24. Turn the test beam so that the finished surface is

to the side and centered in the loading assembly. Operate

the testing apparatus until the loading blocks are brought

into contact with the upper surface of the beam. Be sure

to secure full contact between the loading (and

supporting) surfaces and the beam. If the surface of the

specimen is so rough that full contact is not secured,

grind the specimen to secure full contact.

2. Apply the test load at a rate such that the increase

in extreme fiber stress in the beam is between 125 and

175 pounds per square inch per minute. The extreme

fiber stress corresponding to any load maybe estimated

from the equation given in Step 4a below. Obtain

readings on the proving-ring dial, and convert them to

corresponding total loads in pounds by applying the

proving-ring constant. Aside from the reading used to

control the rate of application of the load, the only

reading necessary is the one that corresponds to the

maximum load applied to the beam.

3. After the specimen has broken, obtain dimen-

sions of the cross section at which failure occurred to

the nearest 0.1 inch. These dimensions represent the

average width and average depth of the section in

failure.

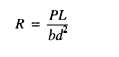

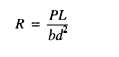

4. The flexural strength, expressed in terms of

modulus of rupture, is given in psi, and can be

calculated as follows:

a. If the specimen broke within the middle third

of the span length, use the following equation:

Where:

R

= modulus of rupture (in psi)

P

= maximum applied load (in pounds)

L

= span length (in inches)

b

= average width of specimen (in inches)

d

= average depth of specimen (in inches)

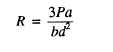

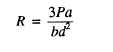

b. If the specimen broke outside the middle

third of the span length by not more than 5 percent of

the span length, calculate the modulus of rupture as

follows:

Where:

R

=

P

=

a

=

b

=

d

=

c.

modulus of rupture (in psi)

maximum applied load (in pounds)

distance (in inches) between the line of

fracture and the nearest support, measured

along the center line of the bottom surface

of the beam

average width of specimen (in inches)

average depth of specimen (in inches)

If the specimen broke outside the middle

third of the span length by more than 5 percent of the

span length, discard the results of the test.

5. The report of the test for flexural strength should

include the following information:

a.

b.

c.

d.

e.

f.

g.

h.

Identification number

Average width to the nearest 0.1 inch

Average depth to the nearest 0.1 inch

Span length

Maximum applied load

Modulus of rupture to the nearest 5 psi

Defects in specimen

Age of specimen

Values of the modulus of rupture vary widely,

depending on the concrete tested. Specification relative

to concrete pavements frequently require modulus of

rupture in excess of 600 to 650 psi (28-day curing,

third-point loading). The flexural strength (modulus of

rupture) generally may be expected to be approximately

15 percent of the compressive strength for comparable

conditions of age and curing.

An approximate relationship between modulus of

rupture and compressive strength can be calculated from

the following formula:

Where:

f ´c

= compressive strength (in psi)

R = modulus of rupture (in psi).

13-33