motorized) type of jack. Three proving rings are

available with capacities of 2,000, 5,000, and 7,000

pounds, respectively. The surcharge weights are used to

approximate (within + 5 pounds) the expected weight of

the pavement and base in the field. The tripod

attachment (when fitted with a dial indicator) and the

swell plate are used to measure the expansion, or swell,

of the material in the CBR mold. Other items needed to

perform the test are equipment and tools, such as a

balance or scale, a CBR mold, a 10-pound tamper,

mixing bowls, spoons, spatulas, a soaking tank or

bucket, and moisture canisters.

Preparation of Test Samples

When a bearing-ratio test is made of a compacted

sample, you will use the 6-inch-diameter CBR mold

with a 2 1/2-inch spacer disk in the mold beneath the

sample. The use of the spacer reduces the depth of the

sample to 4 1/2 inches. The use of another size spacer

will result in volume and compactive effort changes that

may not meet ASTM or other recognized standards for

the CBR test.

The method of preparing the test specimens and the

number of specimens depend upon such factors as the

type of airfield or road and the soils encountered at the

site. The soil sample should be tested in the laboratory

at a density comparable to the density required at the

construction site. There are situations where moisture

conditions are favorable and the subgrade will not

accumulate moisture approaching a saturated condition.

In these cases, samples should be tested at a moisture

content that approximates actual moisture conditions

expected during the time the road or airfield is used. In

all other conditions, the samples are laboratory tested in

a saturated condition.

The saturated condition is attained by soaking the

sample. First, place the sample in the mold and compact

it. The compactive effort used and the number of

compacted samples required depend upon the soil type,

weight and type of field compaction equipment, and

other job conditions. Normally, compactive efforts of

12, 26, and 55 blows per layer (for five layers) are used

in each of three successive compaction tests. The

10-pound tamper is used for compacting the samples.

After compacting the sample, trim it and remove the

base plate and spacer disk. Then place a piece of filter

paper over the trimmed or struck-off top of the sample

and place the base plate over this top. Turn the mold over

and set it in a bucket on the base plate. The bottom of

the sample, which was next to the spacer disk during

compaction, is now uppermost. Apply the appropriate

13-12

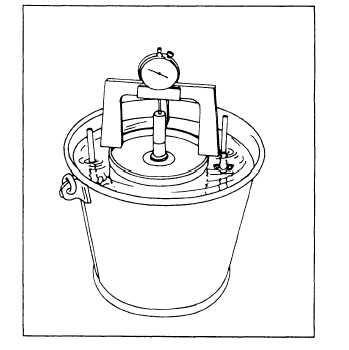

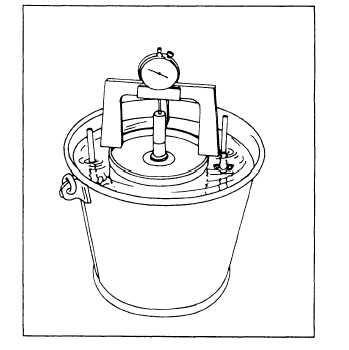

Figure 13-10.—Apparatus for soaking a CBR test sample.

number of surcharge weights needed to approximate the

expected in-place weight of the pavement and base. One

5-pound surcharge weight is equivalent to 3 inches of

overlying material. Then set in place the tripod

attachment, dial, and swell plate, as shown in figure

13-10.

Immerse the mold and the sample in water in the

bucket and leave them to soak for about 4 days. An initial

reading of the tripod dial is made when the sample is

first placed in the water. Then, at the end of the soaking

period, the dial is read again to determine the amount of

swell. A swell in excess of 3 percent of the initial height

of the specimen is considered to be excessive. After

making the final reading of the dial, you remove the

sample and mold from the water and allow them to drain

for about 15 minutes before conducting the penetration

test.

Penetration Test

In the penetration test, the bearing capacity of a soil

is determined by measuring the extent to which the

sample, placed in a mold, is penetrated by a penetration

piston. The sample (in the CBR mold) is placed in the

loading press, as shown in figure 13-9. The piston is

placed on top of the material, and a proving ring is

placed between the top of the piston and the top of the

loading press.

As the jack is cranked upward, the dial in the center

of the proving ring records the pressure being applied to