1.

2.

3.

4.

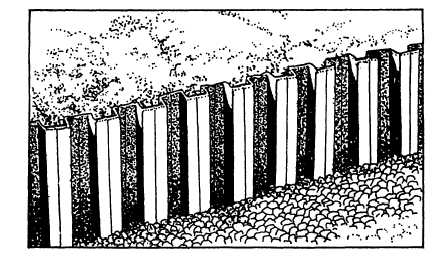

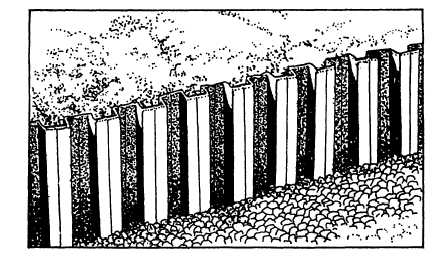

Figure 1-17.—Steel sheet-pile bulkhead.

Pile-and-sheathing bulkhead

Wood sheet-pile bulkhead

Steel sheet-pile bulkhead

Concrete sheet-pile bulkhead

Most bulkheads are made of steel sheet piles, such

as shown in figure 1-17, and are supported by a series

of tie wires or tie rods that are run back to a buried

anchorage (or deadman). The outer ends of the tie rods

are anchored to a steel wale that runs horizontally along

the outer or inner face of the bulkhead. The wale is

usually made up of pairs of structural steel channels that

are bolted together back to back.

In stable soil above the groundwater level, the

anchorage for a bulkhead may consist simply of a buried

timber, a concrete deadman, or a row of driven and

buried sheet piles. A more substantial anchorage for

each tie rod is used below the groundwater level. Two

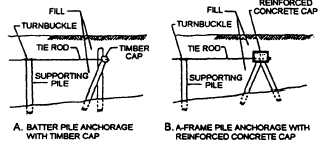

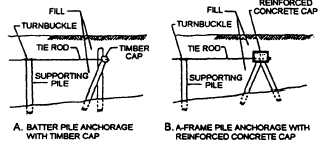

common types of anchorages are shown in figure 1-18.

In view A, the anchorage for each tie rod consists of a

timber cap, supported by a batter pile, which is bolted

to a bearing pile. In view B, the anchorage consists of a

reinforced concrete cap, supported by a pair of batter

piles. As shown in the figure, tie rods are supported by

piles located midway between the anchorage and the

bulkhead.

Bulkheads are constructed from working drawings

like those shown in figure 1-19. The detail plan for the

bulkhead shows that the anchorage consists of a row of

sheet piles to which the inner ends of the tie rods are

anchored by means of a channel wale.

The section view shows that the anchorage will lie

58 feet behind the bulkhead. This view also suggests the

Figure 1-18.—Two types of tie-rod anchorages for bulkheads.

order of construction sequence. First, the shore and

bottom will be excavated to the level of the long, sloping

dotted line. The sheet piles for the bulkhead and

anchorage will then be driven. The intervening dotted

lines, at intervals of 19 feet 4 inches, represent

supporting piles, which will be driven to hold up the tie

rods. The piles will be driven next, and the tie rods then

set in place. The wales will be bolted on, and the tie rods

will be tightened moderately (they are equipped with

turnbuckles for this purpose).

Backfilling to the bulkhead will then begin. The first

backfilling operation will consist of filling over the

anchorage, out to the sloping dotted line. The

turnbuckles on the tie rods will then be set up to bring

the bulkhead plumb. Then the remaining fill, out to the

bulkhead, will be put in. Finally, outside the bulkhead,

the bottom will be dredged to a depth of 30 feet.

To make it possible for ships to come alongside the

bulkhead, it will be fitted with a timber cap and batter

fender piles, as shown in figure 1-20. These piles,

installed at proper intervals, will provide protection

against the impact of ships and will protect the hulls of

ships from undue abrasion.

1-10