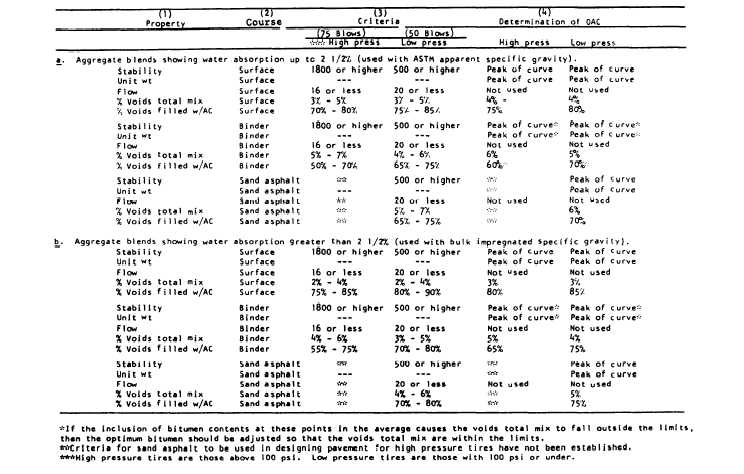

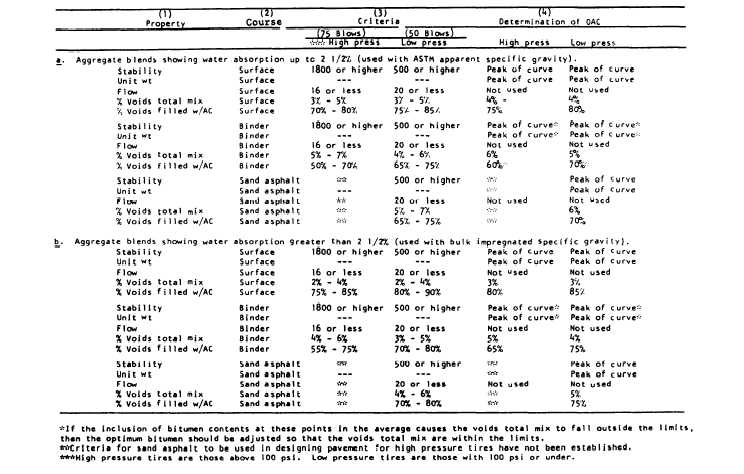

Table 17-7.—Marshall Test Specifications and Determination of Optimum Asphalt Content

5. Calculate the voids by using the adjusted

specific gravity, and apply the design criteria for this

value.

6. Use stability and flow values as measured on the

compacted specimens.

JOB-MIX FORMULA (AC MIXES)

When the mix has proven itself to be satisfactory,

the percentages by weight of the aggregate and the

averaged optimum bitumen content should be combined

to establish the job-mix formula. Figure 17-6A lists the

final percentages of the aggregate for a given job mix.

By plotting the test results (figs. 17-9A and 17-9B) on

DD Form 1219 (fig. 17-10) and applying the Marshall

test criteria for determining optimum bitumen content,

you make the determination that the mix requires

4.7 percent of asphalt cement. Accordingly, the

aggregates must be 95.3 percent of the total mix. The

selected blend contained 45-percent coarse aggregate

(CA), 30-percent fine aggregate (FA), 20-percent fine

river bar sand (FRBS), and a 5-percent limestone dust

(LSD) mineral filler. The job-mix formula is computed

as follows:

CA

= 95.3 x .45

FA

= 95.3 x .30

F R S

= 95.3 x .20

Mineral filler

= 95.3 x .05

Asphalt cement =

Total =

= 4 2 . 9%

= 2 8 . 6%

=

19.0%

=

4.8%

95.3%

4.7%

100.0%

MODIFIED TEST FOR COLD-MIX

PAVEMENTS

This method is used as an aid in determining the

asphalt content for cold-mix design of light-duty

pavement. It can be used where asphalt cutbacks will be

17-21