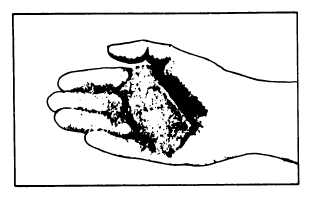

Figure 17-2.—Wet sand.

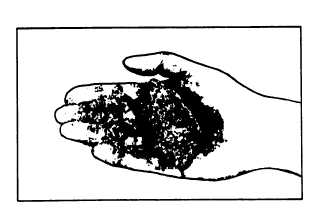

Figure 17-3.—Very wet sand.

The procedure for adjusting the mixing water

caused by free surface moisture is as follows:

. Determine the approximate FSM of the fine

aggregate by the squeeze test.

. Estimate the FSM of the coarse aggregate by

observation. Usually, 2-percent FSM is the maximum

amount gravel will hold without actually dripping.

. Multiply the percentages of FSM on the

aggregates by their respective weights per cubic yard.

This will yield the weight of the FSM on the aggregates.

. Divide the total weight of the FSM by 8.33

pounds per gallon to determine the number of gallons

of water. Subtract those gallons from the mixing water

requirements in the original mix design.

. If you are batching your concrete mix by weight,

you need to account for the weight contributed by the

FSM by increasing the total weights of the aggregates

per cubic yard by the weights of the FSM.

Example Problem: Using the final mix proportions

as determined, adjust the design mix to account for

6-percent FSM on the fine aggregate (FM = 2.70) and

2-percent FSM on the coarse aggregate. Original mix

design for a 1-cubic-yard trial batch was

Cement:

6.49 sacks (Type IA)

Water:

36.6 gallons

Coarse aggregate:

1,735.0 pounds

Fine aggregate:

1,153.0 pounds

Air content:

5.0 percent

Step 1. Determine the amount of water (in gallons)

on the coarse and fine aggregate.

l

l

l

Coarse aggregate

= 1,735 x 0.02 = 34.70 pounds

Fine aggregate

= 1,153 x 0.06 = 69.18 pounds

Total weight of water

= 103.88 pounds

Converted to gallons

= 12.47 gallons

Step 2. Adjust the original amount of mixing water

by subtracting the amount of water contributed by the

aggregates. The adjusted water requirement then is

24.13 gallons (36.6 - 12.47).

Step 3. Adjust the weights of the aggregates by the

amount contributed by the water.

. Coarse aggregate

= 1,735 + 34.7

. Fine aggregate

= 1,153 + 69.18

= 1,770 pounds

= 1,222 pounds

Step 4. The adjusted mix design to account for the

actual field conditions is now

Cement:

6.49 sacks (Type IA)

Water:

24.13 gallons

Coarse aggregate:

1,770.0 pounds

Fine aggregate:

1,122.0 pounds

Air content:

5.0 percent

You should check the moisture content of the aggregates

and make appropriate adjustments as conditions change

(such as after rains, after periods of dryness, or when the

new material arrives). This quality control step assures

that the desired concrete is produced throughout the

construction phase.

Materials Estimation

After proportioning the mix, you must estimate the

total amount of material needed for the job. This is

simply done by computing the total volume of concrete

17-9