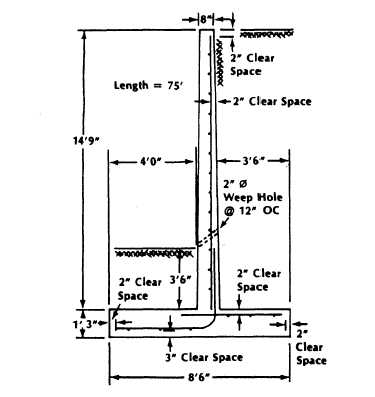

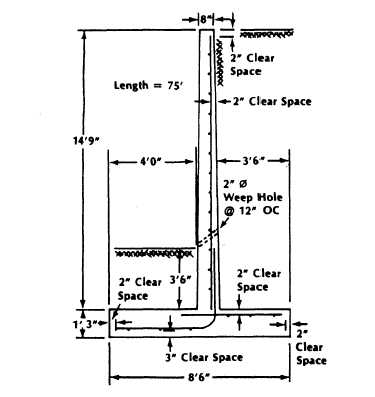

Figure 17-4.—Retaining wall.

to be poured, adding a waste factor, and multiplying this

volume times the amount of each component in the

1-cubic-yard mix design. The manner of doing this is

described in the following example.

Example Problem: Using the mix design deter-

mined previously in this chapter, determine the total

amount of materials needed to construct the

75-foot-long retaining wall shown in figure 17-4. The

1-cubic-yard mix design is recapped below.

Cement:

6.49 sacks (Type IA)

Water

36.6 gallons

Coarse aggregate:

1,735.0 pounds

Fine aggregate:

1,153.0 pounds

Air content:

5.0 percent

To determine the total quantity of each of the above

ingredients needed for the retaining wall, you must first

calculate the total volume of concrete required. As you

should know by now, an easy way to do this is to break

the retaining wall into simple geometric shapes and then

determine and accumulate the volumes of those shapes.

Since you should know how to do this, we will simply

say that the total volume of the retaining wall is 63.7

cubic yards. To this figure you add a 10-percent waste

17-10

factor so that the adjusted amount of concrete needed

for the project is 70.07 cubic yards. (Had the initial

volume needed been greater than 200 cubic yards, you

would have used a 5-percent waste factor.)

Now that you know the total amount of

concrete needed, you can determine the total

quantity of each of the concrete ingredients by

simply multiplying the amount of each ingredient

needed for 1 cubic yard by the total amount of

concrete required for the retaining wall. As an

example, you need 1,153 x 70.07 = 80,790.7 pounds,

or 40.4 tons, of fine aggregate for the retaining wall.

The other ingredients are computed in the same way.

That being done, you find that the following

quantities of ingredients are need for the project:

Cement:

455.0 sacks (Type IA)

Water:

2,567.0 gallons

Coarse aggregate:

60.8 tons

Fine aggregate:

40.4 tons

BITUMINOUS MIX DESIGN

Hot-mix bituminous concrete for pavements is a

mixture of blended aggregate filled with bituminous

cement binder. The materials are heated while being

mixed to promote fluidity of the bitumen for thorough

coverage of the aggregate particles. The design of a

bituminous concrete mix consists of the determination

of an economical blend and gradation of aggregates

together with the necessary content of bituminous

cement to produce a mixture that will be durable, have

the stability to withstand traffic loads, and be workable

for placement and compaction with the construction

equipment available.

The procedures described in this section are

performed during the design of a hot-mix bituminous

concrete. They include testing, plotting the results on

graphs, and checking the readings against values from

the design tables. Testing of the ingredients and the mix

is started before and continued throughout the paving

operations. Specific test procedures are not covered in

this discussion; instead, you should refer to chapter 13

of this TRAMAN and to Materials Testing,

NAVFAC MO-330.