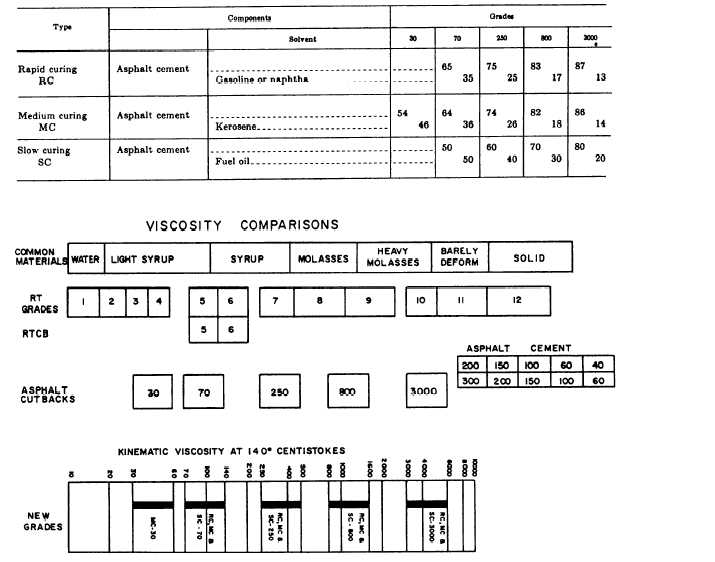

Table 13-5.-Asphalt Cutback Composition (Expressed in Percent of Total Volume)

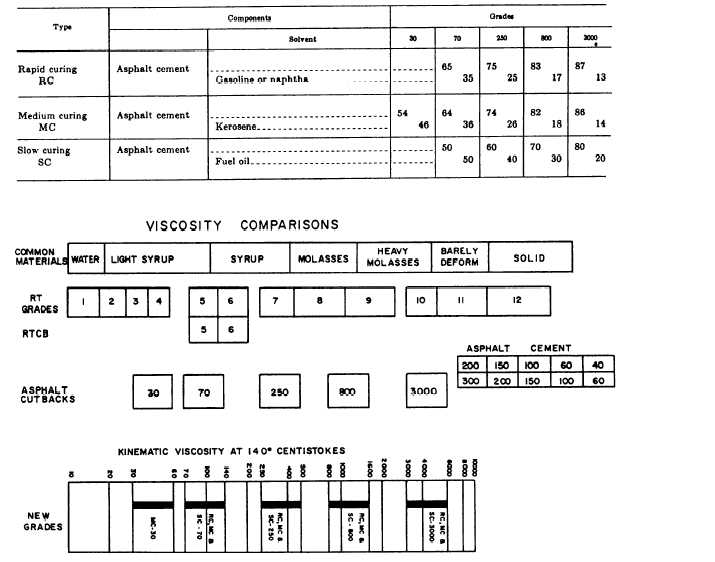

Figure 13-28.-Viscosity grades at room temperature.

exposure to air the solvents evaporate and the asphalt

cement is left to perform its function.

The classification of the cutback is based on the rate

of evaporation of the distillate that is in the mixture.

Gasoline or naphtha (highly volatile) will produce a

rapid-curing cutback (RC); kerosene (medium

volatility), a medium-curing cutback (MC); and a fuel

oil (low volatility), a slow-curing cutback (SC). At

times, reference will be found to road oils, which are one

of the SC grades of liquid asphalt, or in effect, a heavy

petroleum oil. Table 13-5 shows the percentage of

components by grade for the three types of asphalt

cutbacks.

As more cutterstock is mixed with a given amount

of asphalt cement, a thinner liquid results. In practice,

different amounts of cutterstock are added to a given

amount of asphalt cement to obtain various viscosities,

or grades, of cutbacks. The number assigned to each

grade corresponds to the lower limit of kinematic

viscosity measured in stokes or centistokes. The upper

limit of each grade is equal to twice the lower limit or

grade number. Thus a number 70 cutback refers to a

viscosity range of 70 to 140 centistokes. The other

grades and their limits are 250 (250-500), 800

(800-1600), and 3000 (3000-6000); in addition, the MC

has a 30 grade. Figure 13-28 shows the scale of viscosity

grades. The higher the viscosity, the thicker the liquid.

Asphaltic penetrative soil binder is a special cutback

asphalt composed of low penetration grade asphalt and

a solvent blend of kerosene and naphtha. It is similar in

character to a standard low viscosity, medium-curing

13-37