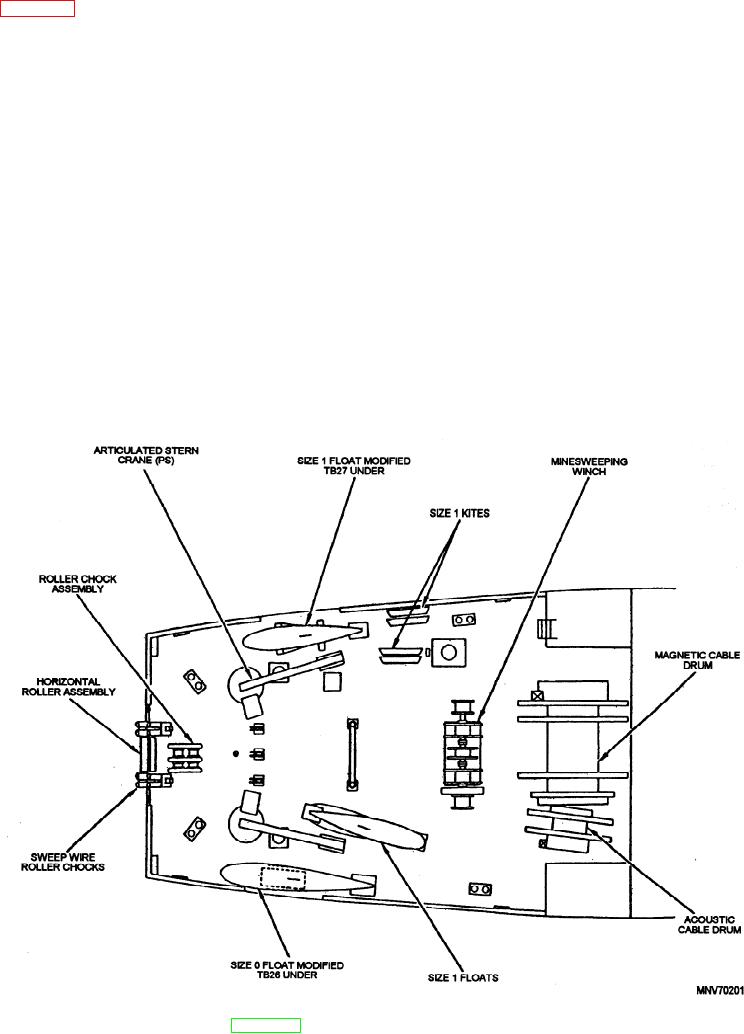

Figure 8-2 shows the position of equipment on an MCM

When the sweepwire contacts a mine mooring cable, the

ship's fantail.

mooring is cut by one of the cutters or, in some cases, by

the sweepwire itself, allowing the buoyant mine case to

During a sweep, a sweepwire is towed from the

rise to the surface, where it can be exploited or

stern of the minesweeper at a depth well below the depth

neutralized.

at which mine cases are expected to be encountered.

Sweepwires may be streamed from one or both sides of

the ship. They are diverted, or spread away from the

MECHANICAL MINESWEEPING

sides of the ship, by an otter attached to their outboard

EQUIPMENT

end and supported by a float attached with a float

pendant.

To this point, we have provided an overview of the

mechanical minesweeping operation. The following

The depth of the sweep is regulated by the length of

paragraphs describe the major individual components

the float pendant. To maintain the entire length of the

of a typical mechanical system, such as the sweep and

sweepwire at approximately the same depth, a

depressor wires, cutters, floats, kites, and bridles.

depressor is secured to the sweepwire near its inboard

end. The depth of the sweepwire near the inboard end is

SWEEP WIRE

determined by the length of the depressor tow wire.

Sweepwires are armed with special cutting devices

A nonmagnetic 5/8-inch, 4,000-foot wire rope with

attached to their outboard end (end cutter) and at

a breaking strength of 32,000 pounds is used as a sweep

intervals along their length (intermediate cutters).

wire for general minesweeping operations.

Figure 8-2.--Equipment on an MCM ship's fantail.

8-2