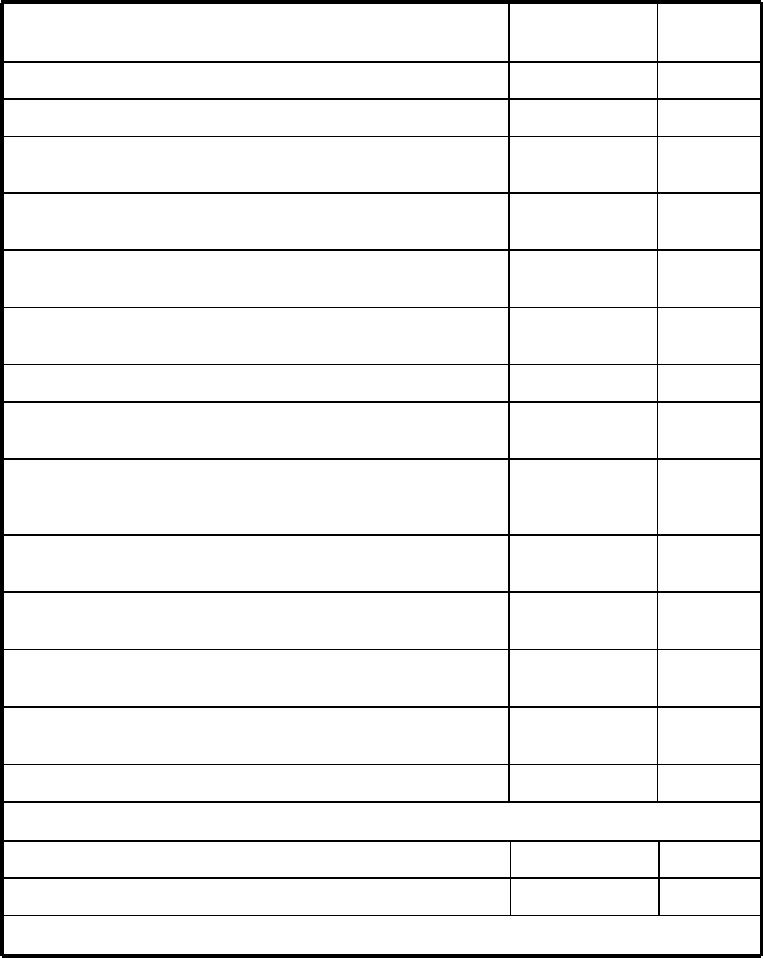

extent of damage. Therefore, you must use sound

The following is an inspection guideline. Rope

judgement to determine the serviceability of a given

technology has not yet advanced to the point where a

section of rope.

rope can be inspected visually to determine the exact

REPLACE

RESPLICE

CHARACTERISTICS

(IF LOCALIZED)

X

1. Rope suspected of being shock loaded.

X

2. Rope has exceeded 75 percent of its minimum breaking strength.

X

X

3. Bulk of surface yarns or strands reduced by approximately 50 percent

for a linear distance equal to four times the rope's circumference.

X

X

4. Three or more adjacent cut yarns in the strands of ropes 5 inches or less

in circumference.

X

X

5. Four or more adjacent cut yarns in the strands of ropes 5 inches of more

in circumference.

X

6. Stretch out: Circumference reduced by 5 percent from circumference

when new.

X

7. Chockling

Wash in mild

8. Oil and grease

detergent

X

X

9. Heavy surface fuzz progressive.

Remove source of

abrasion

X

X

10. Burns or melting visible for a length of over four times the rope

circumference.

X

11. Rust on nylon.

(or clean)

X

X

12. More than four adjacent pulled cover strands (which cannot be

reincorporated into cover braid).

X

X

13. Core visible through cover because of cover damage(except single

braids).

X

14. Core damage - pulled, cut, abraded, or melted strands.

FOR THREE-STRAND AND EIGHT-STRAND PLAITED ROPES

X

X

15. Damage in valley between strands.

X

X

16. Powdering between adjacent strand contact surfaces.

WHEN IN DOUBT REMOVE FROM SERVICE!

4-9