in chapter 613 of the Naval Ships' Technical Manual

Inspect line frequently for deterioration. Open

the lay and inspect the fibers. White powdery

(NSTM), but the more important precautions you should

residue indicates internal wear.

observe are as follows:

Do not drag a line over sharp or rough objects;

Because of the lower coefficient of friction of

doing so can cut or break the outer fibers. When

synthetic-fiber line, you must exercise extreme

line is dragged on the ground, dirt and other

care when you pay a line out or ease it from

particles are picked up and eventually work into

securing devices (bitts, capstans, cleats, gypsy

the line, cutting the inner strands.

heads, etc.). For control in easing out, take no

more than two round turns on cleats or bitts. For

The strength of line exposed to the atmosphere

checking a line under strain, take two round turns

deteriorates about 30 percent in 2 years from

followed by no more than two figure-eight

weathering alone.

bends. Any more than this will present a danger

to personnel and cause difficulty in handling the

Line loaded in excess of 75 percent of its

line.

breaking strength will be damaged permanently.

Inspect the inside threads to see if all or a portion

To minimize the hazard of pulling a line handler

of the fibers in the threads are broken.

into a securing device when a line suddenly

surges, have safety observers ensure that all the

Keep bitts, chocks, and cleats in smooth

line handlers stand as far as possible from the

condition to minimize abrasion.

device, with a minimum distance of at least 6 feet

Use chafing gear on rough, hard surfaces and

from the securing device being tended or

sharp metal edges.

worked. Note that this is particularly critical in

mooring operations.

Apply loads slowly and carefully.

Since a snap-back action inevitably occurs when

SYNTHETIC-FIBER LINES

a line parts under tension, never allow personnel

The synthetic fibers currently in use for making line

to stand in the direct-line-of-pull of the line when

are (in descending order of strength) nylon, aramid,

it is being pulled or when it is under tension. A

polyester (Dacron), polypropylene, and polyethylene.

synthetic line parting under tension will snap

back at near the speed of sound, and there will be

The characteristics of synthetic line differ from

no time to clear the area. Where possible,

those of manila line. This causes the safety precautions

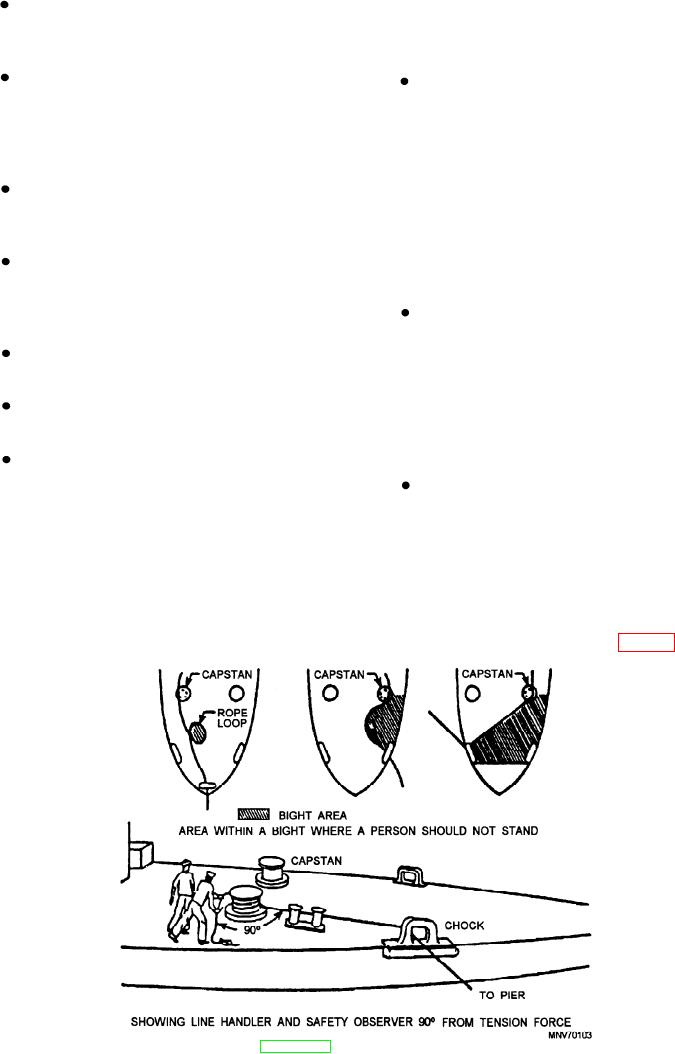

position line handlers a minimum of 90 from the

for synthetic-fiber line to be more exacting than those

for manila line. A complete list of precautions is given

direction of the tension force (fig. 4-7).

Figure 4-7.--Safe working area.

4-5