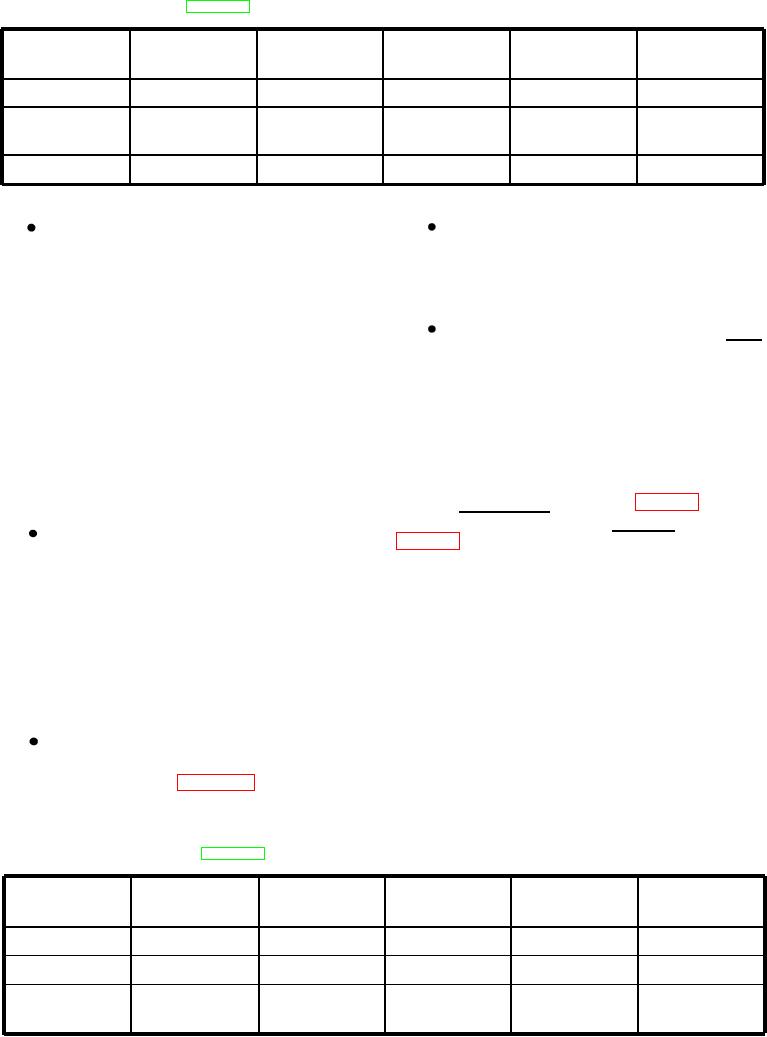

Table 4-1.--Synthetic-fiber-line Constructions and Characteristics

Breaking

Rotation Under

Abrasion

Rope

Cost

Stretch

Strength

Load

Construction

Three Strand

Medium

Good

Highest

LOW

Yes

High

High

Double

Good

LOW

No

Braided

Medium

Good

High

Medium

Plaited

No

Before you begin an operation using synthetic

Never continue to increase the load on a line after

line, determine the capacity of all the gear and

the rigs have been two-blocked or tightened.

fittings used with the line, such as blocks, pad

Many injuries and fatalities have occurred when

eyes, shackles, and line couplings, to ensure that

operators have not observed this rule.

their strength exceeds the minimum breaking

Be sure that a safety observer is posted in every

strength of the rope. Synthetic lines have higher

case where lines are being worked.

breaking strengths than equal sizes of manila

line. Since many of the fittings used in the fleet

Line Characteristics

were designed for natural-fiber line, they may

fail if used improperly with synthetic line.

Lines are classified by both their construction and

Where the substitution of synthetic-fiber line for

their material. The most common line constructions

manila line is authorized, NSTM, chapter 613,

currently used in the Navy are three-strand, double-

provides the appropriate guidance for the

braided, and plaited. The most common properties of

substitution.

the three constructions are shown in table 4-1. The most

common properties of the three materials are shown in

S y n t h e t i c line has poor knot-holding

table 4-2. You can use the information in these tables to

characteristics. Some knots that offer good

determine the construction and material needed for a

characteristics for securing manila line, such as

particular application.

the square knot, are not adequate for belaying or

If, for example, a line must be able to withstand

securing synthetic line. The bowline is one knot

abrasion (abrasion being the condition a line is

known to offer reasonable security when you are

subjected to in a chock or around a capstan head), the

bending together or securing synthetic line.

best choice is a three-strand nylon line. Notice that one

of the characteristics listed in the tables is stretch.

Regardless of the line fiber material, you must heed

Stretch is a misunderstood characteristic in synthetic

the following safety rules whenever you handle line:

line. In some applications of line, excessive stretch is a

Never stand in the bight of a line or in the direct-

disadvantage. In other applications, stretch is an

line-of-pull when the line is being pulled or

advantage. When a line is subjected to impact loading,

under tension. See figure 4-7 for examples of

as it is in towing, the more stretch the line has, the better

it can absorb impact.

Table 4-2.--Synthetic-fiber-line Materials and Characteristics

Rope

Breaking

Abrasion

Stretch

Cost

Strength

Material

toSunlight

Nylon

High

High

Good

Good

High

Low

Polypropylene

Fair

Medium

LOW

Medium

Medium

High

Best

Polyester

Least

Good

(Dacron)

4-6