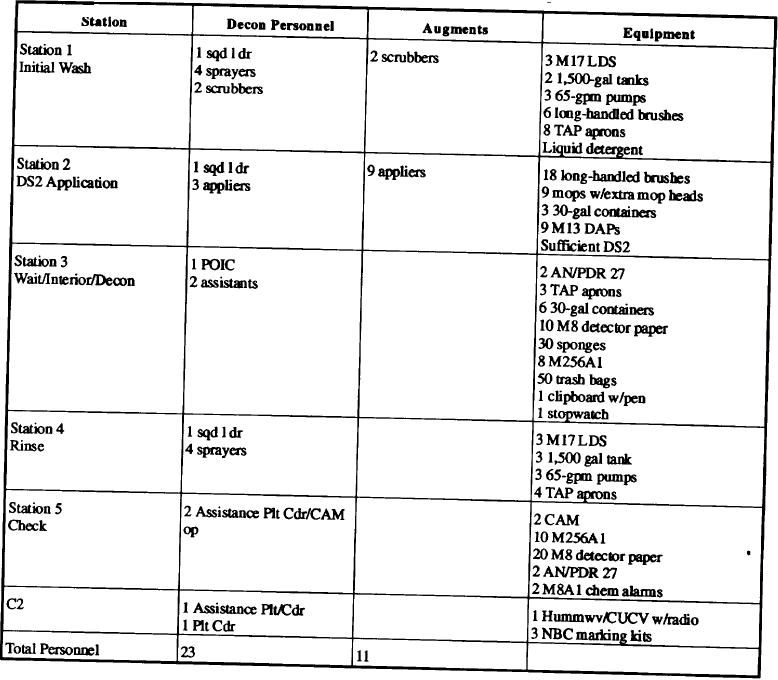

Table 6-9.--Optimum M17 LDS-Equipped DED Setup

This layout uses dual lanes at stations 1,4, and 5

2. Station 2--DS2 Application

to process two vehicles at once. Since the most time

and labor intensive work takes place at station 3, this

3. Station

3--Wait/Interior Decon

station is designed to process three vehicles at a time.

4. Station 4--Rinse

The processing rate of this configuration will be

5. Station

5--Check

affected by any work/rest cycle.

DETAILED EQUIPMENT DECON

DED configurations may vary because of

SUMMARY

organizational and equipment differences. The

optimum configuration provides the maximum output

ALFA company is normally responsible for the

for decon teams at 100 percent personnel and

setup, the operation, and the closure of the DED

equipment. The setup for a DED equipped with a

portion of the thorough decon operation. The COC

M12A1 is different from one equipped with a M17.

will select the DED site. The DED for chemical and

biological contamination consists of five stations:

Both the DED and the DTD must be properly closed

and marked. Once closed, an NBC 4 report must be

1. Station 1--Initial Wash

sent to higher headquarters.

6-32