trigger. The air-control screw regulates the

amount of air supplied to the spreader horn holes

of the cap, thus varying the paint pattern. The

adjustment has a dial that can be set to give the

pattern desired. The fluid needle adjustment

controls the amount of spray material that passes

through the gun. The spray-head locking bolt

locks the gun body and the removable spray head

together.

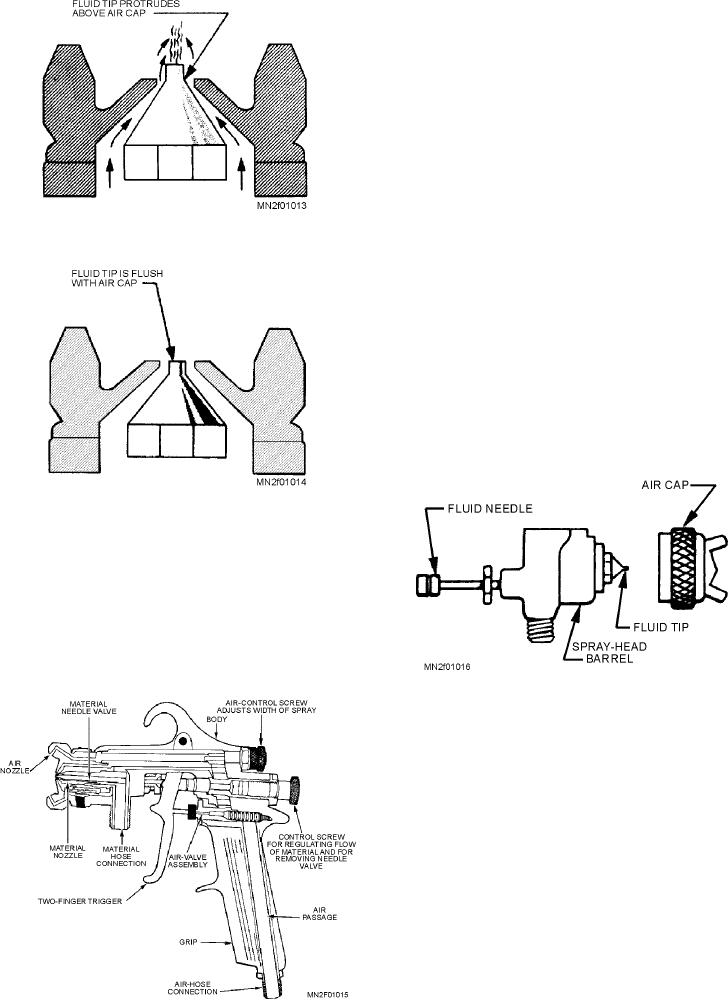

Spray head: Most spray guns have a removable

spray-head assembly. This type of gun has

Figure 1-13.--Suction-feed air cap.

several advantages. For example, it is easier to

clean; it permits you to change the head quickly

when you want to use a new material or a new

color of material; and the head is replaceable

when damaged. The principal parts of the

spray-head assembly are the (1) air cap, (2) the

fluid tip, (3) the fluid needle, and (4) the

spray-head barrel. The fluid tip regulates the

flow of the spray material into the air stream and

encloses the end of the fluid needle. The

spray-head barrel is the housing that encloses the

spray-head mechanism. See figure 1-16.

Figure 1-14.--Pressure-feed air cap.

SPRAY GUN ASSEMBLIES AND COM-

PONENTS.--The two main assemblies of a spray gun

are the gun body and the spray head. Each assembly is a

collection of small parts designed to do specific jobs.

Gun body: The principal parts of the gun body

assembly are shown in figure 1-15. The air valve

controls the air supply and is operated by the

Figure 1-16.--Principal parts of the spray-head assembly.

Material containers: The material containers

are the cups that hold the spray material before

delivery to the gun. The type of painting job

determines which of the several kinds of

containers should be used. Suction-feed cups

are used for small quantities of lightweight and

medium-weight spray materials, such as

lacquers. Gravity-feed cups are small and are

attached directly to the top or side of the gun.

Normally, they are used only on artist's and

decorator's guns or on small touch-up guns.

Pressure-feed cups are best for handling small

quantities of enamels, plastics, or other heavy

materials on jobs where fine adjustments and

Figure 1-15.--Cross section of a spray gun.

speed of application are needed. See figure 1-17.

1-18