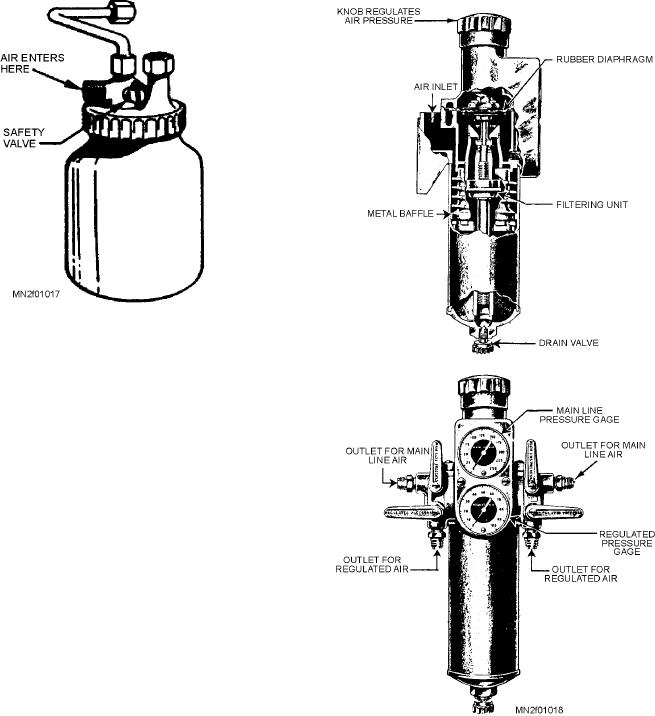

Figure 1-17.--Pressure-feed cup.

Hose lines: The hose lines used for spray guns

are of two types: one handles air; the other

handles liquids. The air hose is usually made of

braid-covered tubing of either one-braid or

two-braid construction. The fluid hose is made

of a special solvent-resistant material that can

withstand the attacks of paint, lacquer, and

similar liquids.

Air supply: The compressed air that operates

spray guns is supplied by either portable or

installed compressors. The air pressure from the

compressors is usually set from 100 to 125 psi.

The pressure is reduced to spraying pressure by a

pressure-regulator valve. When using air

c o m p r e s s o r s , f o l l ow t h e m a n u f a c t u r e r 's

operating instructions. To spray paint properly,

ensure that the air is dry and free of dust. Since

all air contains moisture and dust in varying

amounts, some means must be provided to

Figure 1-18.--Air transformer.

remove it. This is commonly done by an air

transformer, frequently called an air separator or

compressed air through the air inlet opens. The air then

an air regulator. Air, passing through the

passes through the gun body into the spray head. In the

transformer, enters through an air inlet and

most common types of spray heads (external-mix), the

passes through a series of baffles and a filter

air does not come in contact with the paint inside the

chamber to a regulator diaphragm that adjusts

gun, but is blown out through small holes drilled in the

the pressure. During normal weather conditions,

air cap. The paint is blown out of the nozzle in a thin jet.

the transformer should be drained daily. If the

The force of the air striking the paint breaks the jet into

weather is damp, it should be drained several

a fine spray.

times daily. To drain the transformer, open the

drain valve on the bottom of the unit. Change the

You can control this spray to produce various

packing and filter units also at regular intervals.

patterns by setting the air control screw that regulates

See figure 1-18.

the spreader adjustment valve.

To get a round spray, turn the control screw

SPRAY GUN OPERATION.--When the trigger

counterclockwise.

of a spray gun is squeezed, the air valve that admits

1-19