within the specified quarter at the discretion of the

MAINTENANCE REQUIREMENTS FOR

commanding officer or officer in charge.

GROUP 1 ITEMS.--As indicated in table 1-1, all

assembly-level items in maintenance group 1 are

Except in emergency situations as discussed in

subject to class-B criteria at long-cycle maintenance. It

mine maintenance and assembly manuals,

assembly-level items must be subjected to class-B

should be noted that many of these items listed in table

criteria before they are installed in a mine. If a mine is

1-1 of NAVSEA SW550-F0-PMS-010 have had their

upgraded for increased readiness or immediate

long-cycle maintenance period extended to 6 years.

planting, an assembly-level item that is within the

Therefore, when IMAs are performing long-cycle

long-cycle maintenance period may be installed in that

maintenance, they should be aware that an extended

mine without further tests. The maintenance cycle of

maintenance period is appropriate to these items, but

the mine into which a tested spare has been installed

they should also be aware that a local record-keeping

does not change, and the spare component assumes the

system is necessary to determine when the 6-year

maintenance requirements of the mine.

period expires.

Some assembled mines may need to be

MAINTENANCE REQUIREMENTS FOR

downgraded (converted to a lower configuration) or

GROUP 2 ITEMS.--Because of their inherent

completely disassembled, and the assembly-level

items repackaged and returned to stock. In either case,

durability, group 2 items require no programmed or

when such items are returned to stock, they receive

periodic maintenance, visual inspection, or piece-parts

maintenance according to the maintenance group into

inventory following receipt. Upon receipt of group 2

which they fall. Some assembly-level items (such as

items, a visual inspection and piece-parts inventory

arming wires, preformed packings, flat gaskets, and

must also be performed within 12 months of receipt

soluble washers that have been used on a mine) must be

and may be repeated periodically thereafter at the

discarded.

option of local commands.

MAINTENANCE REQUIREMENTS FOR

NOTE

GROUP 3 ITEMS.--Group 3 items are subject to

Items, such as shorting clips, mine crates, and

class-B criteria, as for group 1 items, but only at the

shipping containers, should be retained on board for

time they are selected for installation in the weapon.

use if the mine is downgraded.

MAINTENANCE REQUIREMENTS FOR

GROUP 4 ITEMS.--Items in group 4 need no

After maintenance has been accomplished, the

maintenance whatsoever, except the receipt inspection

items are repackaged in their original packing, if

requirements of NAVSUP P-805.

available. If the original packing is not available, the

items are repackaged according to with Handling,

OTHER MAINTENANCE CYCLES

Packing, Storing, and Transportation of Underwater

Mines and Destructors for Shore-Based/Shipboard

The maintenance of some mines and

Operations, NAVSEA SWO23-AB-WHS-010.

a s s e m b l y - l eve l i t e m s d o n o t fa l l u n d e r t h e

aforementioned maintenance levels and schedules.

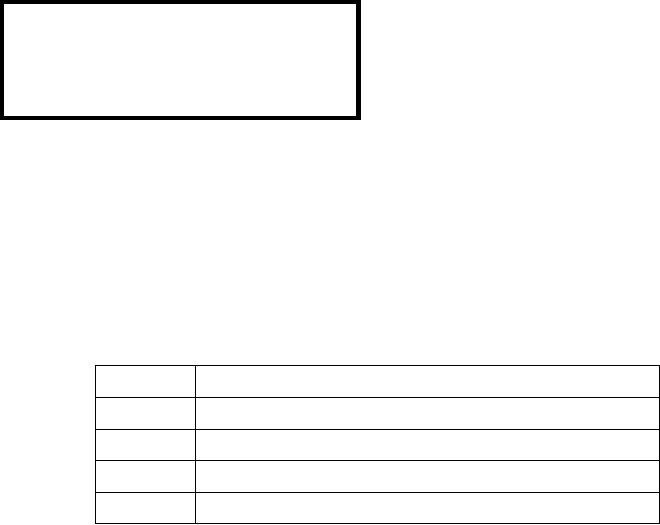

Table 1-1 categorizes the four maintenance groups

This section discusses Conversion Kit Mk 130.

and indicates the maintenance requirements for each.

Table 1-1.--Assembly-Level Item Maintenance Requirements

GROUP

MAINTENANCE REQUIREMENTS

1

Subject to class-B criteria at the time of long cycle maintenance

2

Subject to class-B criteria in conjunction with receipt inspection

3

Subject to class-B criteria before installation/issue

4

Subject to receipt inspection only, per NAVSUP P-805

1-5