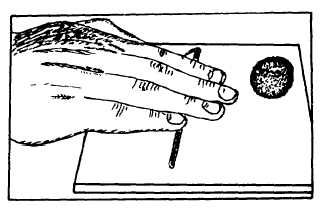

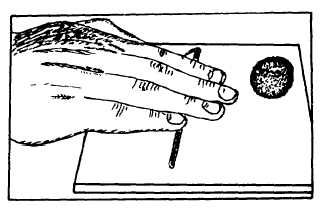

Figure 15-38.-Roll or thread test.

fingers and the test board (fig. 15-38) with just

enough pressure to roll the mass into a thread of

uniform diameter throughout its length. The rate

of rolling should be between 80 and 90 strokes

a minute, considering a stroke to be one complete

motion of the hand forward from and back to

the starting point.

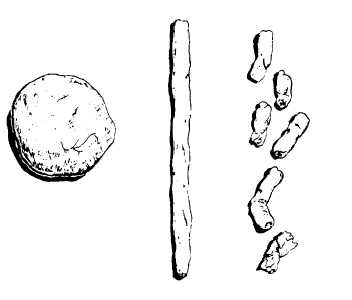

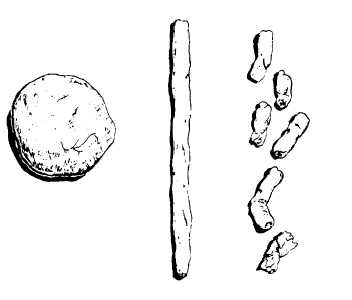

2. When the diameter of the thread has been

reduced to 1/8 in., break the thread into six or

eight pieces (fig. 15-39). Squeeze the pieces

together between the thumbs and fingers of both

hands into a uniform mass roughly oval in shape,

and again roll out into a thread. Continue this

alternate rolling to a thread 1/8 in. in diameter,

breaking, combining together, and rerolling. Do

this until the thread crumbles under the pressure

required for rolling and the soil can no longer be

rolled into a thread. The crumbling may occur

when the diameter of the thread is still greater than

1/8 in. This is considered a satisfactory end point,

provided the soil has previously been rolled into

a 1/8-in. thread at least once.

3. Gather the portions of the crumbled soil

together, place it in the moisture content can, and

determine the water content from the difference

in weight before and after you oven-dry it.

4. Repeat the process on at least two addi-

tional specimens. All three tests should agree

within 1 percent.

The plastic limit is simply the determined water

content.

Plasticity Index

The PLASTICITY INDEX (PI) of a soil is the

numerical difference between its liquid limit and

its plastic limit; that is, PI = LL – PL. The PI

that appears in figure 15-37 means plasticity index.

Figure 15-39.-Roll or thread test sample, before and after

crumbling.

CONCRETE TESTING

Before delving into the remainder of this

chapter, you may find it helpful to return to

chapter 7 and review the topics concerning con-

crete. As you recall, in that chapter you studied

concrete in terms of its use as a construction

material, and you learned of the properties and

requirements that comprise a good concrete. You

also know that when concrete is placed in the field

on a construction project, the concrete used must

satisfy certain specified requirements. It is towards

those properties and various requirements that

concrete testing is directed.

CONCRETE TESTS

In concrete testing, as in soils testing, no single

test will provide all of the information required.

Rather, there is an array of tests that must be per-

formed. The following describes those tests with

which an EA is most commonly concerned.

Aggregate Tests

In order to provide the strongest and most

durable concrete, the aggregate contained in the

mixture must be the best possible in terms of

gradation, shape, strength, and cleanliness.

During the design of a concrete mixture, the

aggregate selected for use must adequately meet

those requirements. To determine this, various

tests are performed. These include tests for

15-34