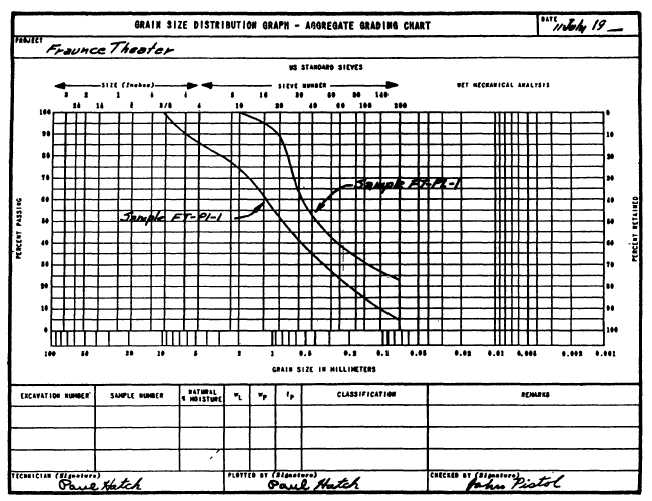

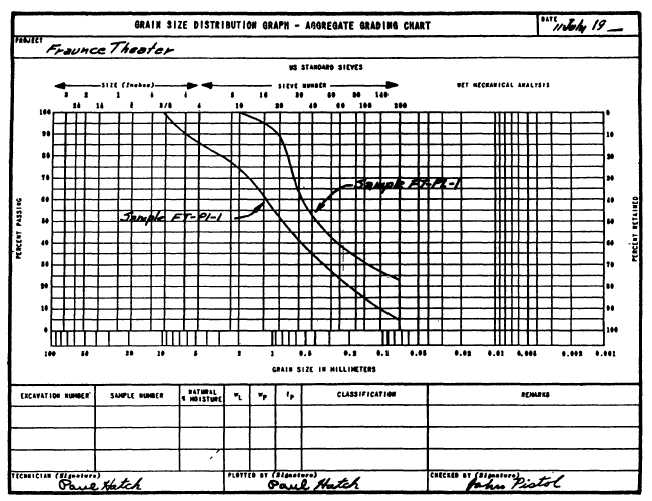

Figure 16-4.—Grain size distribution chart.

You should plot these values on a form like the one

shown in figure 16-4. The graph on this form is a

logarithm type of layout; coordinates horizontally are

sieve sizes (at the top) and grain sizes in millimeters (at

the bottom). Vertical coordinates are percents passing.

The formula for determining

D60 means the grain size, in millimeters, indicated

by the gradation curve at the 60-percent passing level.

In figure 16-4, follow the 60-percent passing line to the

point where it intersects the gradation curve for

FT-P1-1; then drop down and read the grain size in

millimeters indicated below. You read about 1.25mm.

D10 means, similarly, the grain size indicated by the

gradation curve at the 10-percent passing level. In figure

16-4, this is about 0.11mm.

for this sample, then, is 1.25/0.11, or about 11.4.

COEFFICIENT OF CURVATURE

f o r

The

i s a s f o l l o w s :

is as follows:

means the coefficient of curvature of the

gradation curve. Sometimes the symbol

coefficient of gradation) is used instead of

formula for determining

D30 is the grain size, in millimeters, indicated by the

gradation curve at the 30-percent passing level. In figure

16-4, it is (for FT-P1-1) about 0.35. Therefore,

0.352 divided by (0.11 x 1.25), or about 0.89.

FT-P1-1 is obviously a sand, since more than half

of its coarse fraction passes the No. 4 sieve. It is a clean

sand, since less than 5 percent of it (see table AV-1,

appendix V) passes the No. 200 sieve. However, it is not

a well-graded sand (SW), because although its

greater than 6 (prescribed for SW in appendix V), its

is less than 1, the minimum prescribed for SW.

is

is

16-14