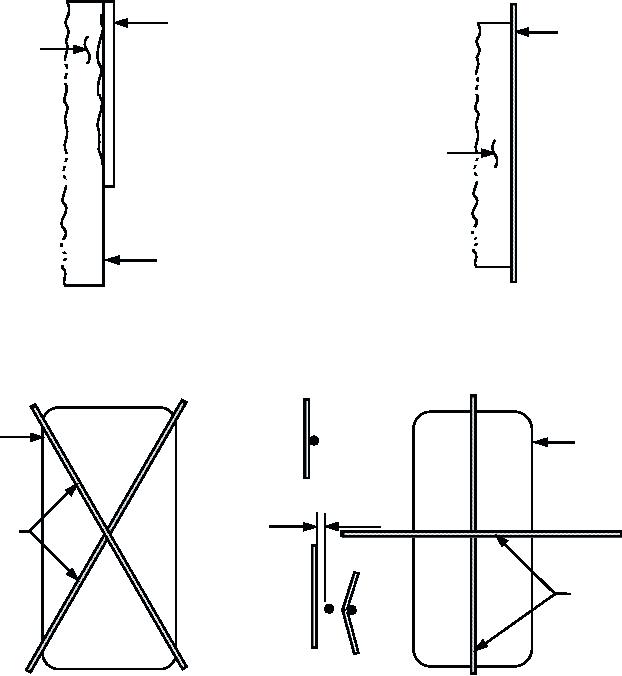

DOOR FRAME

OR

STRAIGHTEDGE

HATCH

PULL

LG = ABT 30"

COAMING

STRING

TAUT

ALONG

DOOR

KNIFE EDGE

FRAME

OR

HATCH

COAMING

KNIFE EDGE

KNIFE-EDGE INSPECTION

KNIFE-EDGE INSPECTION

USING STRAIGHTEDGE METHOD

USING STRING METHOD

SAT

KNIFE

(STRINGS

EDGE

KNIFE

BARELY

EDGE

TOUCHING)

PULL STRINGS

TAUT ACROSS

1/4"

CORNERS

MAX

UNSAT

(STRINGS

TOUCHING

PULL

HARD OR

STRINGS

LARGE GAP

TAUT

BETWEEN

ACROSS

STRINGS)

SIDES

INSPECTION FOR TWISTING

INSPECTION FOR WARPAGE

Figure 3-11. Watertight doorframe inspection.

tolerances, initiate action to replace the closure. For

NOTE

further information, refer to NAVSEA Publication

For detailed instructions for maintenance

S9169-AW-DCB-010.

on watertight doors, refer to Shipboard

P M S C a r d s a n d NAV S E A P u b l i c a t i o n

Inspect the knife-edge for paint, dirt, rust, or nicks.

S9169-AW-DCB-010.

For steel knife-edges, remove paint and rust with #320

grit aluminum oxide abrasive cloth. Be sure to remove

Open the fitting (fig. 3-11). Inspect the knife-edge

the abrasive grit with a clean rag to prevent the grit

for straightness and/or warpage using a straightedge

from getting embedded in the gasket. For aluminum

and two lengths of string. The maximum acceptable

knife-edges, remove paint with a nylon scrubbing pad

variation for knife-edge straightness is plus or minus

and a rag only.

1/8 inch. The maximum acceptable warpage of the

doorframe is 1/4 inch. If frame/coaming warpage is

Inspect the entire knife-edge for proper height. A

block of aluminum cut to the correct specifications is

excessive or if knife-edge straightness is not within

3-9