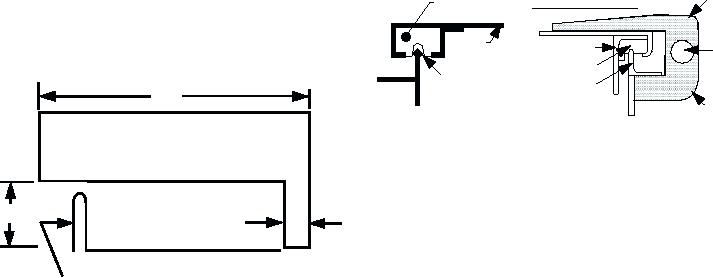

an effective gauge for doing this (fig. 3-12). A

knife-edge that is too high damages the gasket; a

knife-edge that is too low damages the hinges as a

HINGE

WATERTIGHT HATCH

RUBBER

BLADE

result of over-adjusting the door in attempting to

GASKET

maintain a watertight seal. If the knife-edge is more

GASKET

DOOR

RETAINER

than 1/8 inch too high or too short, it must be repaired.

HINGE

PIN

GASKET

BAD GASKET:

KNIFE-

NOTE PERMANENT

EDGE

6"

SET

HINGE

PAD

DCf0313

Figure 3-13. Gasket inspection.

1-11/16"

5/8"

The chalk test is a simple means of determining if

the gasket is in continuous contact with the knife-edge

KNIFE EDGE

when a closure is dogged. A successful chalk test does

DCf0312

not guarantee that a closure is watertight, but if the

gasket is in good condition and the dogs are properly

Figure 3-12. Gauge for measuring knife-edge height.

adjusted, it does provide a reasonable assurance of

watertight integrity.

For steel knife-edges, repair a nicked or short

knife-edge by building up the area with

The steps of the procedure for the chalk test for

corrosion-resistant stainless steel electrode and filing it

doors, hatches, and scuttles are as follows:

with a flat file. Grind a high knife-edge to shorten it to

1. Clean the knife-edge.

the required height. The use of power grinders on a

2. Clean the gasket.

knife-edge is not recommended. Straighten bent

knife-edges by reshaping with a hammer or by bending.

3. Rub chalk on the knife-edge.

For aluminum knife-edges, do not attempt to build

4. Close and dog the closure tightly.

up a short knife-edge. Report the closure to your repair

5. While the closure is dogged down, check for

division for repair. Use only a fine file to file down high

any loose dogs. If any dog is loose, it will need

knife-edges, and avoid leaving grooves in the edge.

to be adjusted and the chalk test repeated.

Use a steel striker plate when hammering a bent

aluminum knife-edge to avoid denting the aluminum.

6. Open the closure and observe the imprint of

chalk on the gasket. The chalk imprint should

Rubber gaskets are installed in watertight closures

be in the center of the gasket. If the chalk line is

to provide a watertight fit all-around when they bear

not continuous, the closure is not watertight

against the knife-edge. Inspect the gasket (fig. 3-13)

and requires further adjustment or repair. For

for the following:

f u r t h e r i n f o r m a t i o n , r e f e r t o NAV S E A

The rubber must be soft and pliable and have no

Publication S9169-AW-DCB-010.

cracks.

Faulty gaskets are a main source of leakage

There should be no paint, rust, or other foreign

through closures. Rubber gaskets (fig. 3-14) are

matter.

installed in doors, hatches, scuttles, air ports, and

The gasket joint should be located at the top of

dogged manholes to provide a tight fit all-around.

When exposed to oil, grease, heat, or paint, the gaskets

the door.

begin to deteriorate. Gaskets should be protected from

There must not be any gaps in the gasket joint.

exposure to substances or conditions that cause

Replace the gasket if shrinkage has caused

deterioration. Replace them immediately when they

separation where the two ends join.

show signs of deterioration. Inspect them frequently to

A permanent set or groove in the rubber may not

detect hardness, cracks, or permanent set (indentation)

greater than 1/8 inch.

be greater than 1/8 inch deep.

3-10