hollow clay tile, concrete brick, tile, or other

similar building units or materials or a com-

bination of these materials, laid up unit by unit

and set in mortar. This section will discuss the

basic masonry materials commonly used in

construction.

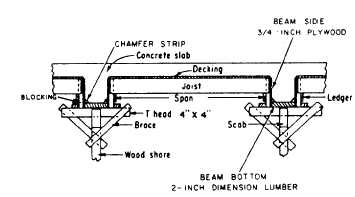

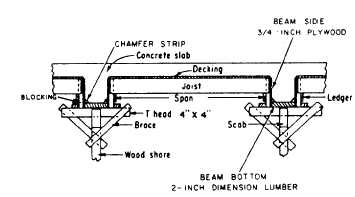

Figure 7-36.-Typical components of beam formwork with

slab framing in.

yoke members come flush with the edges of the

sheathing; on the other two, they project beyond

the edges.

Bolt holes are bored in these

projections, and bolts are inserted to backup the

wedges that are driven to tighten the yokes.

Beam and Girder Forms

The type of construction to be used for

beam forms depends upon whether the form

is to be removed in one piece or whether

the sides are to be stripped and the bottom

left in place until such time as the concrete

has developed enough strength to permit

removal of the shoring. The latter type of

beam form is preferred, and details for this

type are shown in figure 7-35. Beam forms

are subjected to very little bursting pressure

but must be shored up at frequent intervals

to prevent sagging under the weight of the fresh

concrete.

Figure 7-36 shows atypical interior beam form

with slab forms supported on the beam sides. This

drawing indicates that 3/4-in. plywood serves as

the beam sides and that the beam bottom is a solid

piece of 2-in. dimensioned lumber supported on

the bottom by 4- by 4-in. T-head shores. The

vertical side members, referred to in the figure as

blocking, are placed to assist in transmitting slab

loads to the supporting shores.

CONCRETE MASONRY

Concrete masonry has become increasingly

important as a construction material. Important

technological developments in the manufacture

and utilization of the units have accompanied the

rapid increase in the use of concrete masonry.

Concrete masonry walls properly designed and

constructed will satisfy various building re-

quirements including fire, safety, durability,

economy, appearance, utility, comfort, and good

acoustics.

The most common concrete masonry unit is

the CONCRETE BLOCK. It is manufactured

from both normal and lightweight aggregates.

There are two types of concrete block:

heavyweight and lightweight. The heavyweight

block is manufactured from cement, water, and

aggregates, such as sand, gravel, and crushed

limestone. The lightweight blocks use a com-

bination of cement, water, and a lightweight

aggregate. Cinders, pumice, expanded shale, and

vermiculite are a few of the aggregates used in

lightweight block production. The lightweight

units weigh about 30 percent less than the

heavyweight units.

Concrete blocks are made to comply with

certain requirements, notably compressive

strength, absorption, and moisture content.

Compressive strength requirements provide a

measure of the blocks’ ability to carry loads and

withstand structural stresses. Absorption re-

quirements provide a measure of the density of

the concrete while moisture content requirements

indicate if the unit is sufficiently dry for use in

wall construction.

Block Sizes and Shapes

MASONRY

MASONRY is that form of construction

composed of stone, concrete, brick, gypsum,

Concrete block units are made in sizes and

shapes to fit different construction needs. Units

are made in full- and half-length sizes, as shown

7-23