Your correction here will be applied in the

opposite direction. Since the tape reads short, the

laid tape distance of 362.73 ft is LONGER than

362.73 ft by the amount of the total correction

for standard error (0.01 ft). Therefore, you must

SUBTRACT the total tape error. To lay off a

distance of 362.73 ft with this tape, you would

actually measure off a distance of 362.72 ft.

Suppose now that the Bureau of Standards

calibration certificate states that when a tape

indicates 100.00 ft under standard conditions, it

is actually measuring only 99.997 ft. Again, the

standard error is 0.003 ft per 100 ft, but this tape

“reads long”; that is, the interval it indicates

is LONGER than the interval it is actually

measuring. Suppose you measure the distance

between two given points with the tape and find

that the tape indicates 362.73 ft. The total

standard error is again 0.01 ft. Because the tape

reads long, however, the distance it indicated was

longer than the distance it actually measured.

Therefore, the total standard error should be

subtracted, and the distance between the given

points should be finally recorded as 362.72 ft.

Suppose you are using this same tape to set

a point 362.73 ft away from another point. Again,

the total standard error is 0.01 ft. Because the tape

reads long, however, a measurement of 362.73 ft

by the tape will actually be LESS than 362.73 ft.

Therefore, the total correction for standard error

should be added, and you should measure off

362.74 ft by the tape.

CORRECTING FOR TEMPERATURE

VARIATION.— Take again a 100-ft steel tape

that has been calibrated at a standard temperature

of 68°F. The coefficient of thermal expansion of

steel is about 0.0000065 unit per 1°F. The steel

tape becomes longer when its temperature is

higher than the standard and shortens the same

amount when it’s colder. The general formula for

variation in temperature correction is as follows:

From the above formula, you can deduce that

the correction for a 100-ft tape is about 0.00065

ft per 1°F, which is about 0.01 ft for every 15°F

change in temperature above or below the

standard temperature of 68°F.

The temperature correction is applied in the

same manner and direction as the standard tape

error. If the tape measurement is taken at a higher

temperature than standard, the tape will expand

and will read short; naturally the correction

should be added.

The error caused by variation in temperature

is greatly reduced when an Invar tape is used.

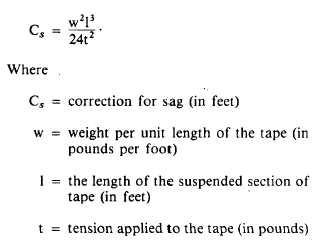

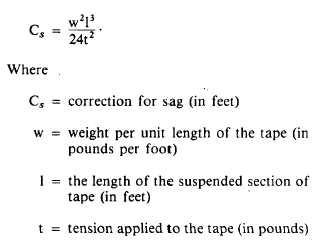

CORRECTING FOR SAG.— Even under

standard tension, a tape supported or held only

at the ends will sag in the center, based on its

weight per unit length. This sag will cause the

recorded distance to be greater than the length

being measured. When the tape is supported at

its midpoint, the effect of sag in the two sections

is considerably less than when the tape is

supported only at its ends. As the number of

equally spaced intermediate supports is increased,

the distance between the end graduations will

approach the length of the tape when supported

throughout its length. The correction for the error

caused by the sag between the two supports for

any section can be determined by the following

equation:

For full tape-length measurements, the

correction for sag is usually taken care of by

having the tape calibrated. The tape must be

calibrated regardless of how it is supported and

under standard temperatures and tension. To

reduce the value of the horizontal correction for

sag, the Bureau of Standards suggests standard

12-17