Figure 6-5.-Grain direction in a sheet of plywood.

Dry from the mill, plywood is never “green.”

From ovendry to complete moisture saturation,

Figure 6-3.-Laminated and sawed lumber or plywood

a plywood panel swells across or along the grain

beam.

only about 0.2 of 1 percent and considerably less

with normal exposures.

There is probably no building material as

versatile as plywood. It is used for concrete forms,

wall and roof sheathing, flooring, box beams,

soffits, stressed-skin panels, paneling, partitions,

doors, furniture, shelving, cabinets, crates, signs,

and many other purposes.

Sizes

Plywood is generally available in panel widths

of 36, 48, and 60 in. and in panel lengths ranging

from 60 to 144 in. in 12-in. increments. Other sizes

are also available on special order. Panels 48 in.

wide by 96 in. long (4 by 8 ft), and 48 in. wide

by 120 in. long (4 by 10 ft), are most commonly

available. The 4 by 8 ft and larger sizes simplify

construction, saving time and labor.

Nominal thicknesses of sanded panels range

from 1/4 to 1 1/4 in. or greater, generally in

1/8-in. increments. Unsanded panels are available

in nominal thicknesses of 5/16 to 1 1/4 in. or

greater, in increments of 1/8 in. for thicknesses

over 3/8 in. Under 3/8 in., thicknesses are in

1/16-in, increments.

Types

Plywood is classified by type as INTERIOR

or EXTERIOR. Made of high-quality veneers and

more durable adhesives, exterior plywood is

better than interior at withstanding exposure to

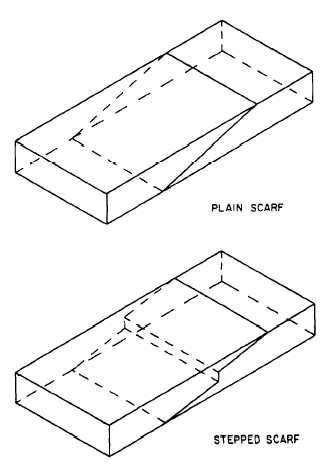

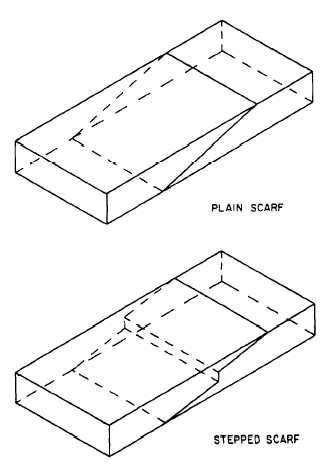

Figure 6-4.-Scarf joints.

the elements. Even when wetted and dried

6-9