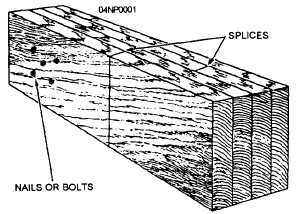

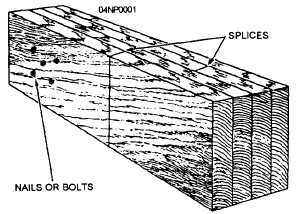

Figure 6-1.-Examp1e of a laminated lumber.

a board 1 ft long by 1 ft wide by 1 in. thick. Since the

length of lumber is usually measured in feet, the width

in inches, and the thickness in inches, the formula for

the quantity of lumber in board feet becomes the

following:

Example: Calculate the board measure of a 14-ft

length of a 2 by 4. Applying the formula, you get

Lumber less than 1 in. thick is presumed to be 1 in.

thick for board measure purposes. Board measure is

calculated on the basis of the nominal, not the dressed,

dimensions of lumber. The symbol for board feet is bm,

and the symbol for a unit of 1,000 is M. If 10,000 board

feet of lumber were needed, for example, the quantity

would be 10Mbm.

LAMINATED LUMBER

Laminated lumber is commonly used when

increased wood load-carrying capacity and rigidity are

required. Usually made of several pieces of 1

1/2-in. -thick lumber, called laminations, the pieces are

nailed, bolted, or glued together with the grain of all

pieces running parallel (fig. 6-1). When extra length is

needed, the pieces are spliced with the splices staggered

so that no two adjacent laminations are spliced at the

same point. Built-up beams and girders are examples

of laminated lumber.

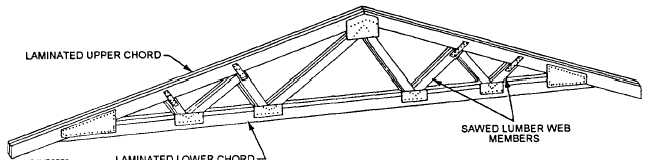

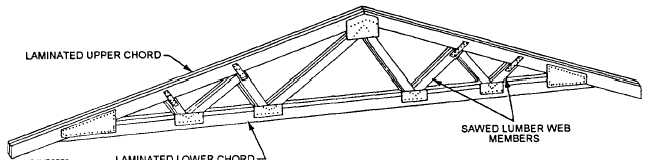

Laminations may be used independently or with

other materials in the construction of a structural unit.

Trusses can be made with laminations for the chords

and sawed lumber for the web members (fig. 6-2).

Special beams (fig. 6-3) may be constructed with

laminations for the flanges and sawed lumber for the

webs.

Probably the greatest use of laminations is in the

fabrication of large beams and arches. Beams with

spans larger than 100 ft and depths of 8 1/2 ft have been

constructed with 2-in. boards. Laminations this large

are factory-produced. They are glued together under

pressure. Most laminations are spliced using scarf

joints (fig. 6-4), and the entire piece is dressed to ensure

uniform thickness and width.

PLYWOOD

Plywood is a panel product made from thin sheets

of wood called veneers. An odd number of veneers,

such as three, five, or seven, is generally used so the

grains on the face and back of the panel run in the same

direction. Cross-lamination (fig. 6-5) distributes the

grain strength in both directions, creating a panel that

resists splitting and, pound for pound, one of the

strongest building materials available.

Figure 6-2.-Truss using laminated and sawed lumber.

6-8