Laser Method of Laying Pipe

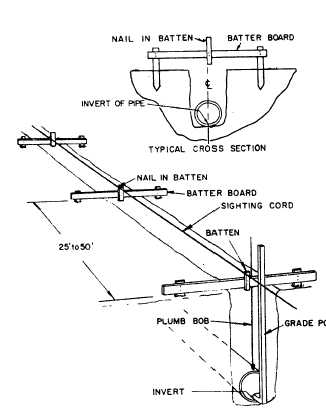

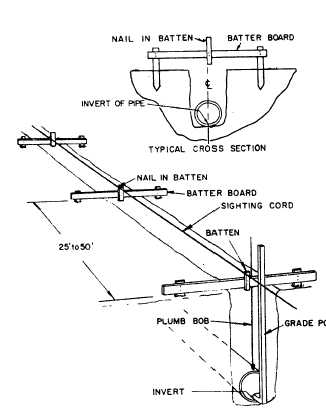

Figure 10-20.—Setting sewer line to grade.

subtract the specified cut from 10 feet. At station 8 +

50, for example, the height of the top of the batter board

above the top of the hub would be 10 – 5.55, or

4.45 feet.

The offset is measured off from a point directly

above the hub along the batter board; a mark here is

directly over the center of the pipeline. Battens are

nailed on the batter board to indicate sewer center-line

alignment. A string is stretched and tacked along

these battens; this string indicates the horizontal loca-

tion of the line and follows the gradient of the line, but

at a distance of 10 feet above the invert. The amount

of cut required to be taken out at any point along the

line can be determined by setting a measuring pole

alongside the string. If the string indicates 8.5 feet, for

example, another 1.5 feet of cut must be taken out.

Corners of rectangular manhole boxes are staked

out much as building corners are staked out. For a box

located where a line changes direction, it may be desired

that the center line of the box bisect the angle between

the lines. The box for a curb inlet must be exactly

located with respect to a street curb to be constructed in

the future; therefore, curb inlets are usually staked out

with reference to the street plan, rather than with refer-

ence to the sewer plan.

Another useful device for controlling pipeline

excavations and laying pipe is the laser. So many

applications are being found for the laser that it may

eventually be the only tool needed for the layout and

control of construction projects. It can be quickly,

accurately, and economically used for purposes such

as distance measurement, alignment for tunnel

borings, setting of pipes with desired grades, and

setting of line and grade for many types of

construction.

The laser is an intense light beam that can be

concentrated into a narrow ray, containing only one

color (red) or wavelength of light. The resulting beam

can be projected for short or long distances and is

clearly visible as an illuminated spot on a target. It is

not disturbed by wind or rain, but it will not penetrate

fog. A laser can be set up on a bracket or even attached

to a transit telescope. The beam is aligned in the proper

direction at the desired grade and can be left relatively

unattended.

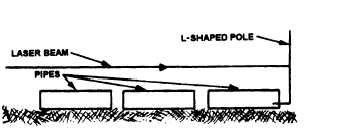

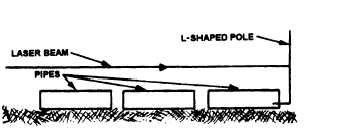

Today, instead of using batter boards and strings,

lasers can be used to control the alignment for excavat-

ing trench and setting a pipe. The laser can be set so that

it shines on the boom of a backhoe so that the equipment

operator can clearly see the illuminated spot. By its

position, the operator can closely control the depth of

digging. For laying the pipe, the laser is set in the proper

direction at the desired distance above the pipe invert.

With the aid of the L-shaped pole or templet, as shown

in figure 10-21, the workmen can control the invert

elevation. It may also be possible to direct the laser

beam from the inside of manholes through the pipes

being laid and to control the grade without any interfer-

ence from the backill operations. This can be done even

if the pipes are too small for human access.

Underground Duct System Layout

The stakeout for an underground power line is

similar to that for a sewer. For the ducts, cuts are

Figure 10-21.—Pipe laying with a laser.

10-21